Point-of-Use Waste Gas Treatment with STYRAX

The STYRAX tool family uses burn/wet technology and was specifically developed to manage demanding waste processes like CVD processes in the semiconductor and photovoltaic industries. The media supply of the systems can be carried out variably. Longer maintenance cycles increase the system’s uptime.

Waste Gas Treatment – STYRAX

Treatment of Waste Gases with STYRAX

The development of the STYRAX product family bases on two significant aspirations for modern waste gas treatment: Improved PFC abatement and Reduced Maintenance Intervals. Therefore, new technological approaches have been introduced in the portfolio of DAS Environmental Expert. The gases are now burnt from top to bottom. The scrubbing stage is optimized for HF. Water and/or lye consumption are minimized. A special inlet design prevents clogging. Further options are available to improve maintenance intervals in other processes

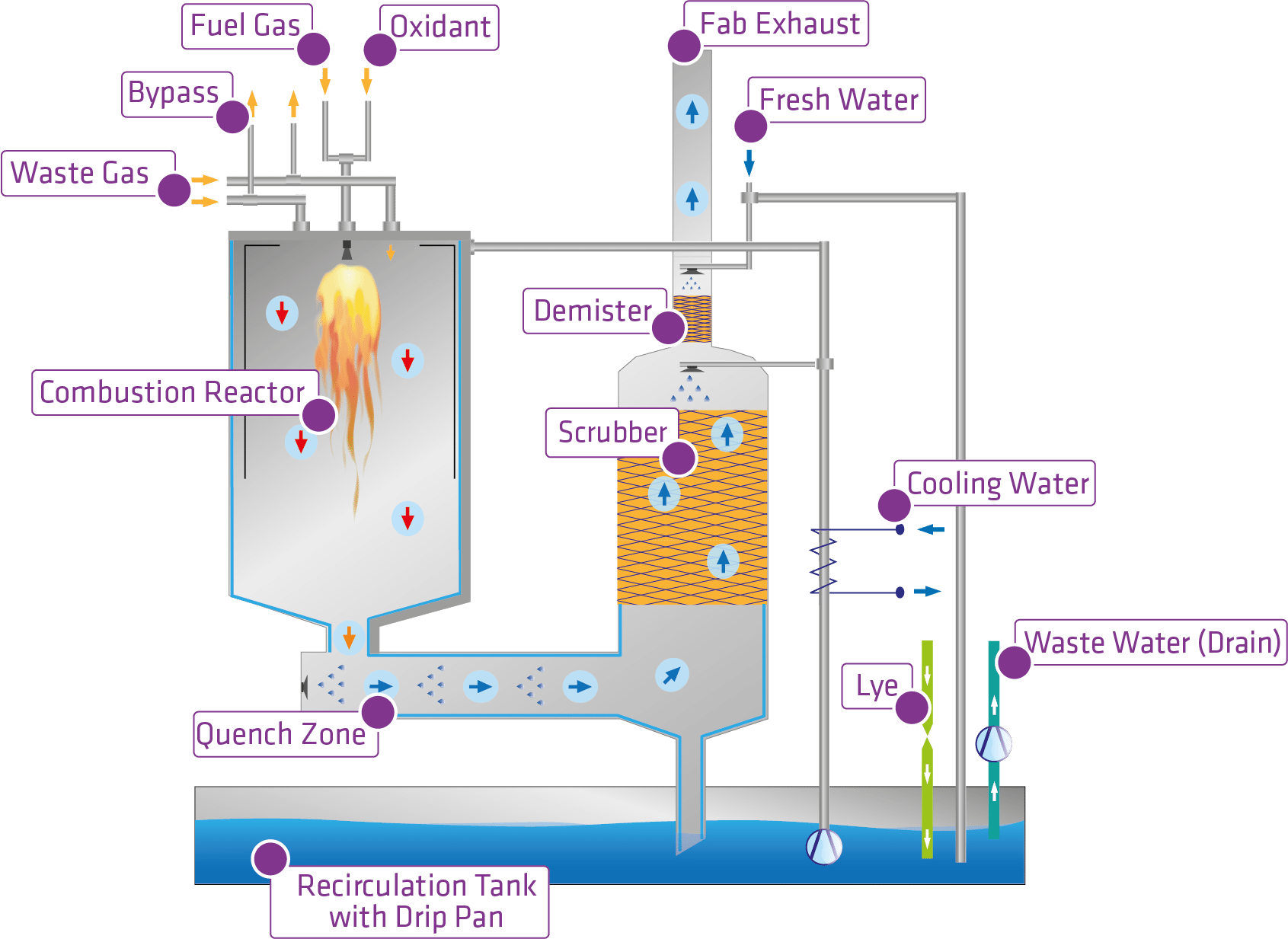

Operating Principle of STYRAX Waste Gas Treatment Systems

Hazardous substances of process waste gases are treated directly from where they originate (Point-of-Use). In this optimized burn/wet technology the gases are burnt from top to bottom. Depending on the chemical composition of the waste gases, various reactions take place (oxidation, reduction, pyrolysis). A fluid wall/film prevents corrosion and deposition of particles in the reactor. In the washing column next to the reactor, soluble components are absorbed and particles suspended. The scrubbing liquid cools down and neutralises combustion products such as hydrogen halides. With the application of STYRAX within a holistic abatement concepts, manufacturers in the high-tech industry will meet the strict standards of the German air pollution law (TA Luft).

STYRAX DUO – Waste Gas Treatment with Backup-Function

STYRAX DUO is our standard version. Two scrubbing systems operate simultaneously. The system is optimised for up to four independent inlets of semiconductor and photovoltaic process tools. In case of malfunction or maintenance on one reactor, the other backs up the treatment of all waste gases (internal back-up), which ensures the equipment’s near 100 % operation time. STYRAX DUO runs with different fuel gases and scrubber liquids. Access for operation and maintenance is found in the front and back. It is characterized by low water consumption through a closed-loop design.

Specifications

- Up to 2 independent inlets per reactor

- Operation time > 99% through backup function

- Second reactor allows uninterrupted operation during maintenance

- Runs with different fuel gases

- Low water consumption through closed-loop design

Further Product Versions – without Back-Up System

STYRAX INLINE is optimised for up to six independent inlets of semiconductor and photovoltaic process tools.

STYRAX TWICE is a double-system with two independent burn/wet systems with a common control and media supply. It is optimised for up to eight independent inlets of semiconductor and photovoltaic process tools.

Technical Data

| STYRAX INLINE | STYRAX TWICE | |

|---|---|---|

| Dimensions (W x D x H): | 1110 mm x 675 mm x 2070 mm | 1865 mm x 675 mm x 2070 mm |

| Maintenance area: | Front and back side | Front and back side |

| Gas entry: | 6 x DN25 oder 4 x DN40 | 2 x 4 DN25 oder DN40 |

| Gas outlet: | DN100 | 2 x DN100 |

Options

The following equipment options are available for all STYRAX systems:

- Power Supply: 3 x 400 V/50 Hz or 3 x 208 V/60 Hz

- Fuel Gas: NG, LPG

- Oxidant: O2, CDA

- Closed-loop system: Water, Lye

- Heated feed lines and inlets

- Process-Tool-Interface

- Signal Tower

- Drip Pan

- Earthquake Safety Kit

- Monitoring

- SEMI S2 certification

Certificate