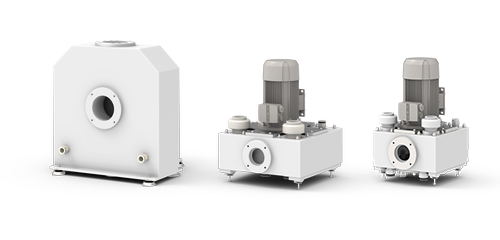

Point-of-Use waste gas treatment by rotary fine dust collector RDC/RDC MINI/RDC MICRO

The systems of the RDC series use centrifugal force to separate the fine dust particles. They are based on the purely mechanical rotor-stator principle.

Waste Gas Treatment – RDC series

Treatment of Waste Gases with RDC

The RDC range offers solutions for production plants that create very high fine dust loads. It is an efficient extension of the EDC range; DAS Environmental Expert GmbH thus offers perfectly adapted solutions for different sectors and processes.

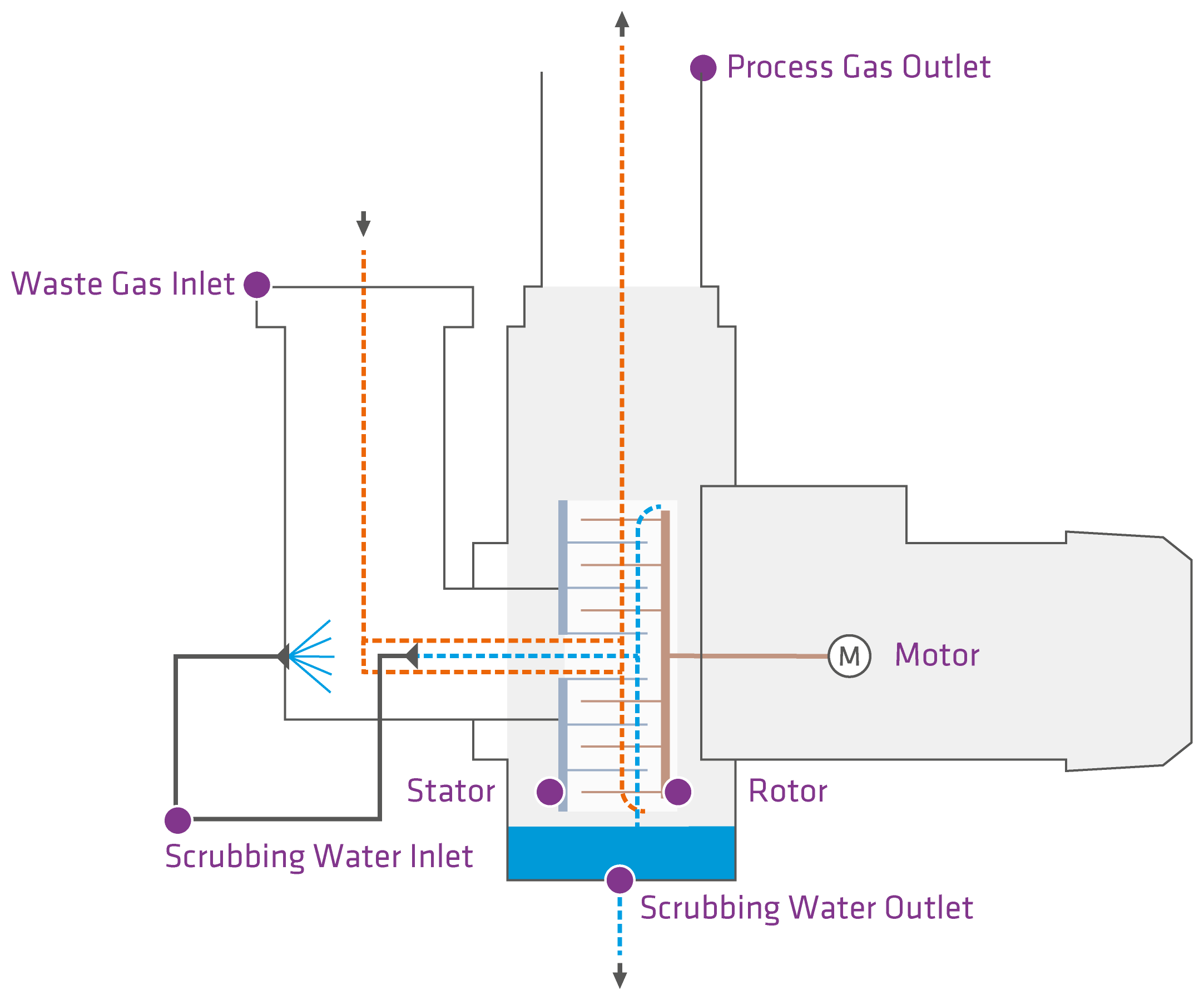

Functioning principle of the RDC rotary fine dust collector

A jet of water is atomised by a high-speed rotating disc. The result is a mist of very fine water drops in which dust particles are centrifuged. The rotor ensures that the waste gases are aspirated and thus moved forward without loss of pressure. The turbulence in the shear gap between the rotor and stator ensures that the water mist and particle-laden process gases are mixed together effectively. The fine dust particles are suspended in the water; the purified waste gas can then be released freely into the environment.

RDC – Reducing micro- and nanoparticle emissions at the point-of-use

The RDC range was developed by DAS Environmental Expert GmbH in response to a client’s request. The systems are small, which means they can be integrated into or added to the classic burner-scrubber systems and can reach a capacity of 120 – 390 m³/h (depending on the model).

Specifications

- Integrated or on top dust solution for DAS burn/wet abatements

- Available in different sizes and capacities 120–390 m³/h

- Centrifugal principle without high-voltage fields

- Particle efficiency 80 to98%

- Low maintenance

Technical Data

- Capacity (RDC/RDC MINI/RDC MICRO): 6500/3000/2000 slm

- Max. dust concentration : 40000 mg/m³

- Fresh water: 0.5 — 5.0 l/min

Options

| RDC | RDC MINI | RDC MICRO | |

|---|---|---|---|

|  |  |

|

| Max. flow [m³/h]: | 390 | 180 | 120 |

| Rated power [kW]: | 2.2 | 1.1 | 1.1 |

| Dust removal efficiency [%]: | SiO2 > 80% WO3 > 95% | SiO2 > 80% WO3 > 95% | SiO2 > 80% WO3 > 95% |

| Max. dust concentration [g/m³]: | 40 | 40 | 40 |