Case studies of pilot plants for wastewater treatment

Not all wastewater is the same. The wastewater specialists at DAS develop cost-effective plant solutions which guarantee the best wastewater treatment results possible for our customers. After initial laboratory testing, we often run a pilot plant under real-life conditions directly at the customer’s site to ensure that the plant configuration is optimal.

Biological treatment of wastewater from the cosmetics industry

Emil Kiessling GmbH of Georgensgmünd contacted DAS Environmental Expert GmbH because the organic load in its wastewater, even after a chemical and physical pretreatment stage, was still too high for indirect discharge. A pilot plant was used from June to November 2006 to find a way to successfully treat the wastewater from the cosmetics manufacturer by biological means.

The planned new biological plant was intended to enable the treatment of wastewater from a wide range of product lines, each of which entail very different pollutant loads and foam formation. Moreover, the company is located close to a residential area, necessitating strict observance of noise and air protection codes.

Testing was conducted to assess treatment with a TFR (trickle flow) bioreactor (a proprietary method from DAS). The trial run was conducted to determine potential space savings and rate of biodegradation, as well as the operating costs (including chemical and energy consumption) under real-life conditions. In 2010, DAS Environmental Expert GmbH used this as the basis for constructing a large-scale facility consisting of three trickle flow reactors, via which the company can safely discharge its wastewater into the sewer system.

Biological treatment of landfill wastewater

The AMAND Group runs a class II landfill at its site in Grumbach, Saxony. Disposing of the wastewater from its landfill proved to be problematic since the seepage that accumulates can have properties which inhibit biodegradation. Furthermore, the nitrogen load exceeded the official limit for indirect discharge and the hydrogen sulfide content posed a serious odor nuisance to the residents of the nearby housing district.

After initial laboratory trials, our wastewater specialists ran a pilot plant directly on site from November 2011 to March 2012. They used a biological procedure in which the organic pollutant load was reduced and the ammonium was converted into nitrate by aerobic means in the first step of the process. The wastewater treatment then continued with an anoxic reactor, in which external carbon is added to convert the nitrate into harmless gaseous nitrogen.

Once the procedure had been successfully tested, the system was scaled up to a technical facility consisting of three specially adapted TFR bioreactors, which went into operation in 2013. The plant consistently handles a nitrogen load of 38.4 kg/d which must be degraded. The ammonium concentration upon intake amounts to roughly 800 mg/l, while the total nitrogen content upon discharge is less than 150 mg/l. The sulfide content has been reduced from 280 mg/l upon intake to less than 1 mg/l upon discharge. This ensures that the cleaned water is also odor-free and can be treated further by the municipal sewage treatment plant.

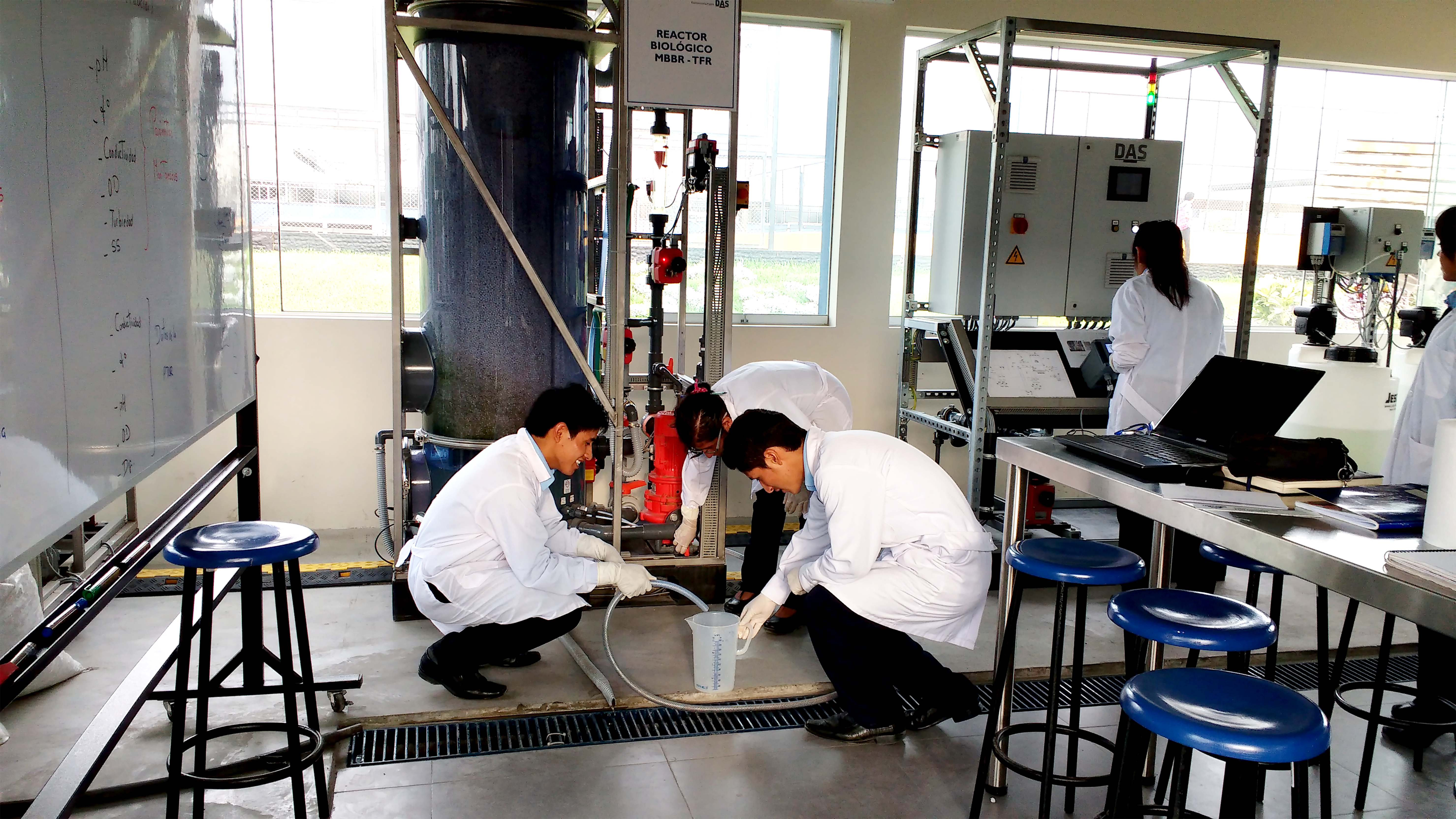

Training of environmental engineers at modern demonstration plants in Peru

The experts at DAS Environmental Expert GmbH have constructed pilot plants for demonstrating various wastewater treatment methods at the Peruvian vocational training institution, Senati. They serve to demonstrate the TFR and MBBR methods, for which purpose the plant has been combined with an additional UV disinfection stage.

Running from October 2014 to October 2017, the project was intended to support the training of environmental engineers in Peru. Modern wastewater treatment technologies have not yet been put to widespread use in this Latin American country, so demand for training and experience in the field of wastewater treatment is generally very high there.

DAS Environmental Expert GmbH took charge of building and commissioning two pilot plants at training sites in Lima and Piura. The teaching staff was also trained accordingly and familiarized with the biological wastewater treatment methods (TFR / MBBR) – an important step in rectifying the lack of qualified personnel in the field of wastewater treatment.

Seminars for private companies and state institutions can also be carried out at the demonstration plants. The technologies as well as their application and combination possibilities are presented and explained in this context.

Further processes and products for wastewater treatment

Your contact person for all questions on wastewater treatment