Eliminating NOx in the Semiconductor Industry

Acid rain and heavy smog – these threats to health and nature are caused by NOx (Nitrogen oxides NO2 and NO). Dealing with harmful NOx, which is generated in combustion processes, is a real challenge in many industries. DAS Environmental Expert has now developed a turnkey solution for NOx treatment, suited for semiconductor and other industries.

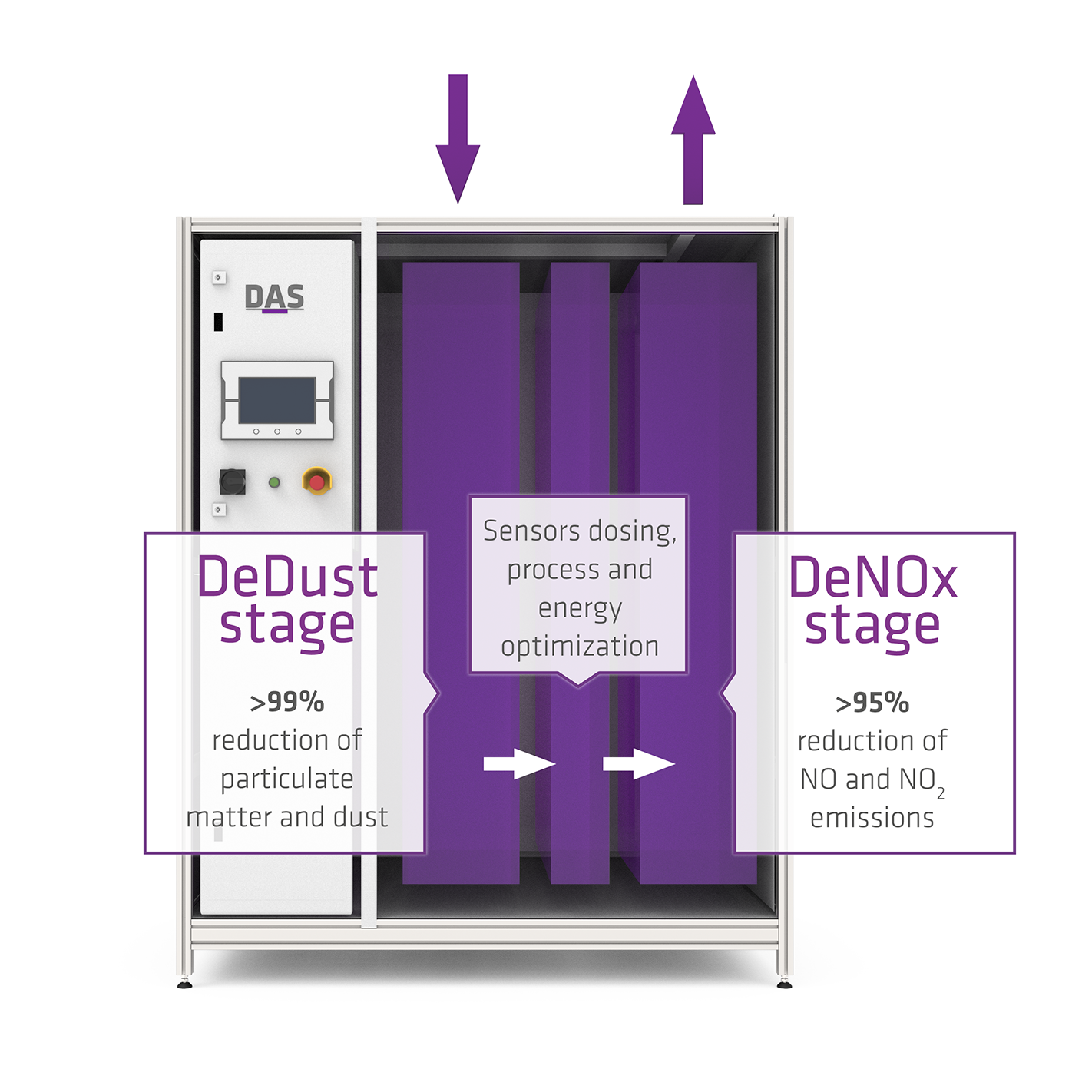

DeDust-DeNOx Point-of-Use abatement solution by DAS

National environmental regulations such as TA-Luft Germany or EPA USA set strict limits for NOx emissions. Therefore, not only major NOx emittents like power plants, waste incinerators, or Diesel generators, but also high-tech industries like the semiconductor industry are in need of an effective solution.

DAS is at the forefront of NOx reduction in the semiconductor industry. As a leader of innovation in the semiconductor abatement industry, DAS has developed a solution for NOx treatment. This approach is an efficient and reliable option for NOx treatment in high-tech fabs as well as other industrial and non-road applications.

The Point-of-Use abatement solution DAS DeDust-DeNOx focuses on treating NOx (NO2, NO), fine dust (PM1, PM2.5, PM10), and particulate matter in small to medium sized waste gas streams up to 200m³/h and 1500 ppm NOx – and is proven to reduce NOx emissions by more than 95%; dust emissions by more than 99%.

State of the art technology

The DAS abatement solution for NOx and dust treatment combines state of the art technology: a high efficiency DeDust filter system and DeNOx selective catalytic reduction technology.

In the DeDust stage, more than 99% of particulate matter (SiO2 and other particles) is captured. This filtration prevents clogging of the subsequent components and the following catalyst, thus also securing the best catalytic activity over time.

The subsequent DeNox stage makes use of a technology that is a proven to convert NOx into nitrogen (N2) and water: selective catalytic reduction (SCR). Thanks to the SCR catalyst, NOx reduction of more than 95% and emission levels of 5 ppm can be reached. With the DAS DeNOx system, state of the art DeNOx catalysts are used, supplied by one of the renown catalysts suppliers . Ammonia (NH3) which is used for the reduction of NOx, is dosed automatically. Internal sensors ensure a precise control and low overall media consumption. With our design we can ensure the efficient treatment of varying NOx concentrations at all times as well as the long-term catalytic activity.

Real-time monitoring is also integrated in the DeDust-DeNox solution: The abatement is equipped with online NOx emission measurement; monitoring for additional parameters (NH3-slip, CO and other emissions) is also available on request. This enables an optimized control of all relevant parameters and ensures TA-Luft and EPA conformity. The generated data is ready to be used for governmental regulatory matters and documentation purposes.

DAS Environmental Expert is your partner in the reliable and efficient treatment of NOx. No matter your needs, our experts will find the perfect solution.

Do you want to know more about Eliminating NOx in the Semiconductor Industry?

Contact us for detailed product and commercial information on DeDust-DeNOx.

DAS Environmental

Expert GmbH

Key Accounter Manager

Goppelner Str. 44,

01219 Dresden

GERMANY