Construction of a new flotation system to

optimise biological wastewater treatment at

ARA Rhein

ARA Rhein treats industrial and municipal wastewater from the catchment area in Pratteln in a 2‑stage biological process. DAS Environmental Expert GmbH was responsible for building the new two-line flotation system together with the project partner Enviplan®.

With a total of 500,000 population equivalents, ARA Rhein is the largest wastewater treatment plant of its kind in Switzerland. The plant cleans approx. six billion litres of industrial and municipal wastewater in an environmentally friendly way. For clean wastewater to be discharged into the river Rhine, it must first pass through several elaborate cleaning stages. The wastewater treatment process consists of mechanical, chemical, physical and biological processing stages as well as thermal treatment of the sewage sludge formed during the biological cleaning process. The waste heat generated during incineration of the sewage sludge is fed as heating energy into the “Grüssen” heating network of the company, Elektra Baselland, with headquarters in Liestal (Switzerland). This results in savings of approx. one million litres of fuel oil.

Extensive wastewater analyses guarantee the consistently high quality of the wastewater to be discharged. The legally prescribed limit values are complied with at all times.

Another service offered by ARA Rhein is the cleaning of easily biodegradable wastewater and the environmentally friendly handling of sewage sludge from municipal and industrial wastewater treatment plants. A new waste air concept ensures the almost complete reduction of air pollutant emissions.

The second biological step is loaded with a high suspended-solid content

ARA Rhein treats industrial and municipal wastewater from the catchment area in Pratteln in a 2‑stage biological process. The industrial wastewater is treated in the first stage (1st biological stage). It is then mixed with the municipal wastewater and treated in the following stage (2nd biological stage). In the future, Nitrogen and phosphorous are to be eliminated from the wastewater in parallel to the decomposition of the organic load.

The removal of nitrogen and phosphorous from the wastewater is a basic requirement for the subsequent discharge of the wastewater into the river Rhine. Without this treatment, the increased nutrient deposits would lead to increased growth of phytoplankton and thus to eutrophication of the river.

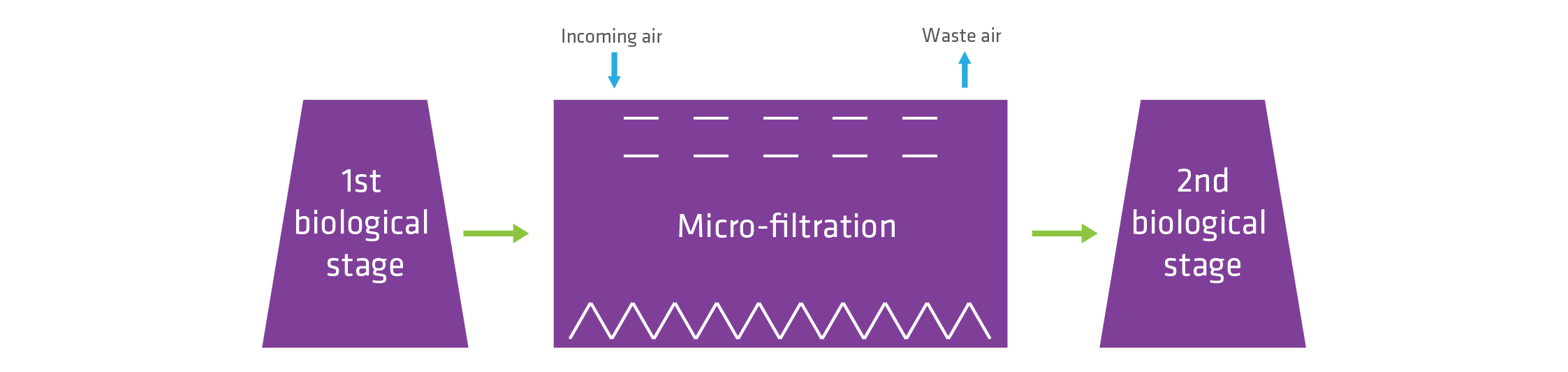

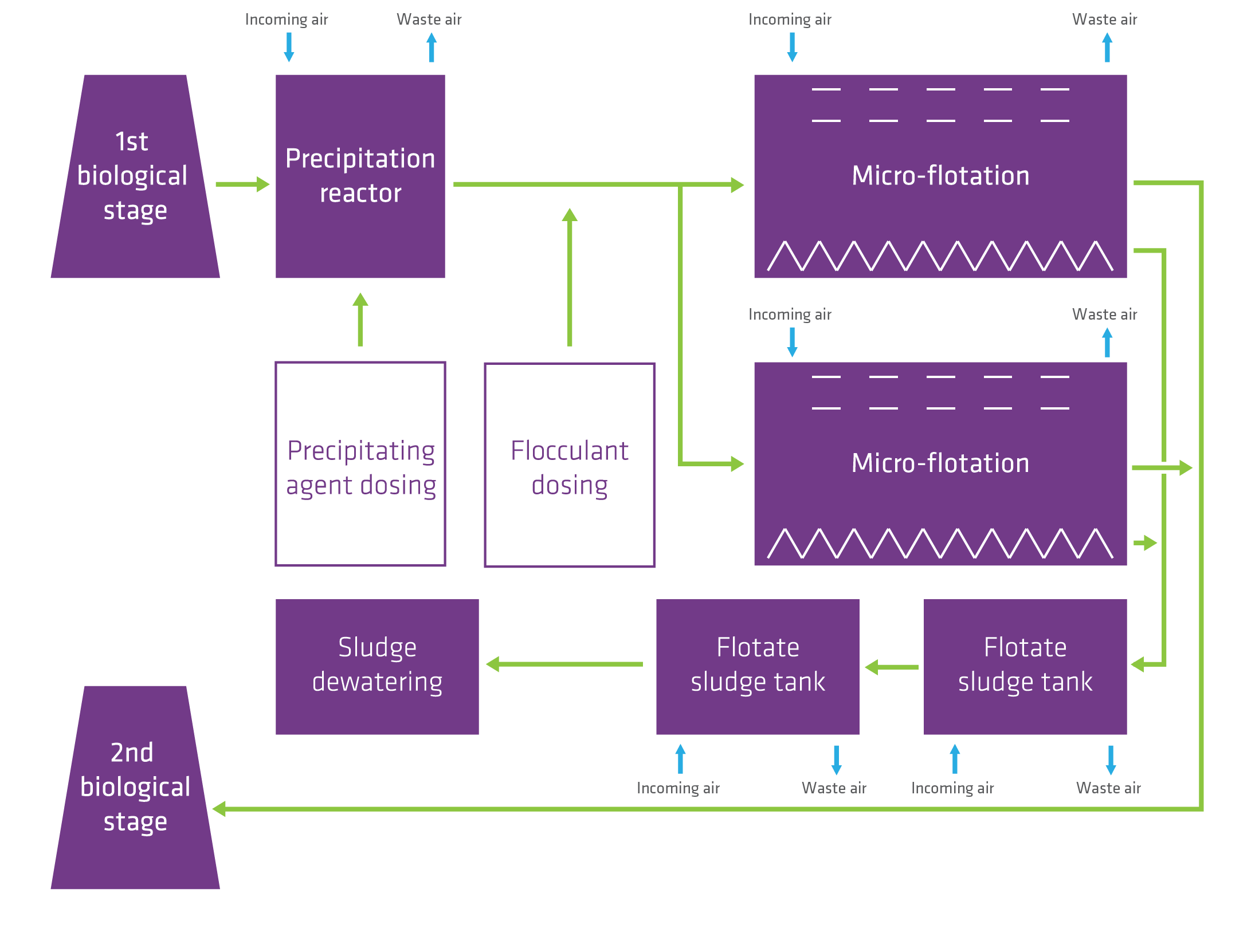

In order to enable problem-free nitrification of nitrogen during the 2nd biological stage in future, reliable retention of the biomass from the 1st biological stage must be ensured. A micro-flotation system was chosen as the method for ensuring efficient retention of the biomass, and thus for avoiding the transportation of large quantities of solids to the second biological stage. With the new flotation system, the second biological stage will, with the present hydraulic load, only be subject to a daily load of total suspended solids (TSS) of approx. 1.3 tonnes compared with the current 2.4 to 8 tonnes.

How the micro-flotation system and its peripheral devices work

Wastewater from the 1st biological stage is also fed into a newly built installation. The installation acts as a pump device for the flotation system and as a precipitation reactor. Polyaluminium chloride is used as the precipitating agent. The flotation system is fed by redundantly designed pumps. A cationic polymer is used as the flocculant. Processing water is used to prepare the polymer solution from a powdery polyelectrolyte, and is heated to approx. 20°C by means of heat exchangers using the waste heat from the wastewater. The two-line micro-flotation system has been installed in such a way that once freed from solids, the wastewater can be guided by gravity to the next biological stage.

Through an extremely high phase boundary, the dense homogeneous microbubbles, which are generated by means of a unique principle, cause >90% of the total suspended solids to separate. The automatic self-cleaning injector and pressure relief valves of the micro-flotation system are another distinctive feature and make the micro-flotation system virtually maintenance-free.

An online turbidity meter with free-fall flow cell monitors the flow of clear water from the two micro-flotation systems.

The flotate has a dry mass content of > 2.5%. The flotate concentration is monitored by a system based on microwave technology. The measuring principle is particularly robust in the face of changes in the colour or in the particle structure of the sewage sludge to be ascertained. The flotate sludge is transferred to the existing sludge treatment system by means of redundantly designed eccentric screw pumps.

Heat recovery for ideal temperature control of the processing water

To prepare the required flocculant, the temperature of the processing water must be at least 20°C. Particularly during the winter months, as the temperature of the processing water extracted from the bank filtrate of the river Rhine is far below 20°C, the waste heat from the wastewater to be treated is used to achieve the required temperature..

The thermal energy from the wastewater is transferred to the processing water by means of a plate heat exchanger. A special brush system prevents the formation of biofilm or other types of deposits on the plates.

Cleaning waste air from the flotation system

Highly polluted waste air is emitted, particularly during the first biological stage (cleaning of the industrial wastewater). This waste air as well as the waste air from the micro-flotation system is burned at 850°C in a regenerative thermal oxidation system. Slightly polluted waste air from the second biological stage or slightly polluted ambient air is cleaned in a special biological filter.

ARA Rhein is thus making an important contribution to keeping the air clean in accordance with the Swiss Ordinance on Air Pollution Control.

DAS, the general contractor for building the new micro-flotation system

The construction of the new micro-flotation system at ARA Rhein was a joint project led by DAS Environmental Expert GmbH from Dresden. In particular it involved project engineering, mechanical equipment and instrumentation as well as commissioning and optimisation of the micro-flotation system.

The intensive technical support that DAS provided at the start of the project won us over. The building work on the new system went smoothly and to schedule.

Your contact person for all questions on wastewater treatment