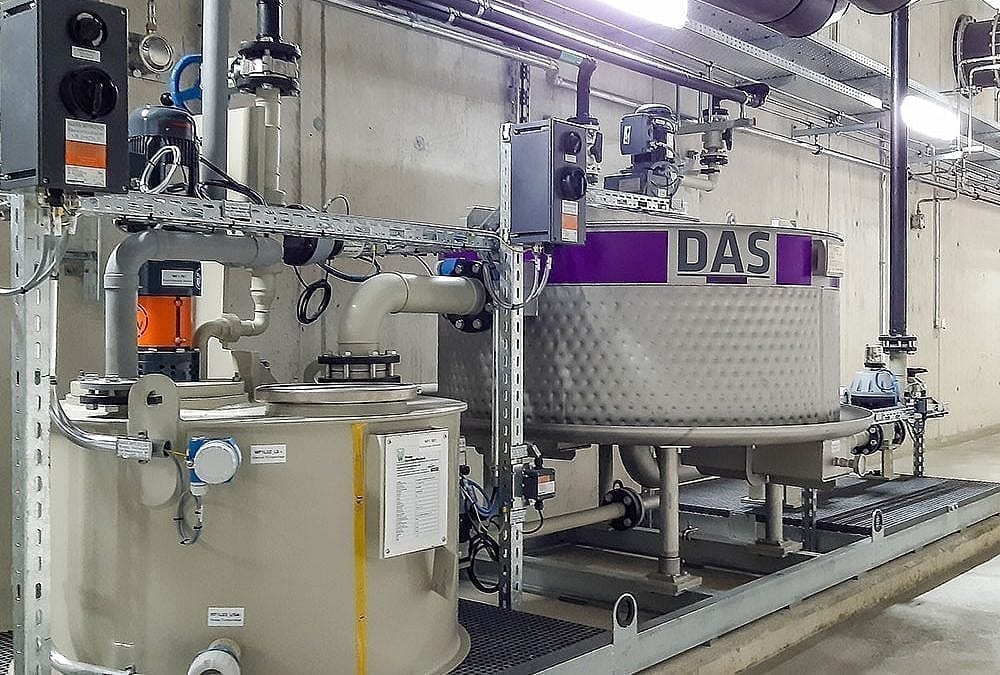

Clean Air and Clean Water for Industries Worldwide

From high-tech manufacturing to dairies — for more than 30 years, we at DAS Environmental Experts have been planning, building, optimising and maintaining waste gas and water systems worldwide. Thanks to our wealth of experience, we know the requirements of a wide range of industries and always offer customised solutions.

Our Core Industries

We offer custom-fit and effective solutions for manufacturers of high-tech products worldwide. Particularly important for us: The protection of people and the environment has the highest priority and should always be in line with the technological development of society.