Efficient Waste Gas Treatment and Water Treatment for the Semiconductor Industry

At DAS EE, we have been specialists in point-of-use abatement technology for over 30 years. Our customers value both our extensive know-how in the abatement of process waste gases and our expertise in the entire field of water treatment.

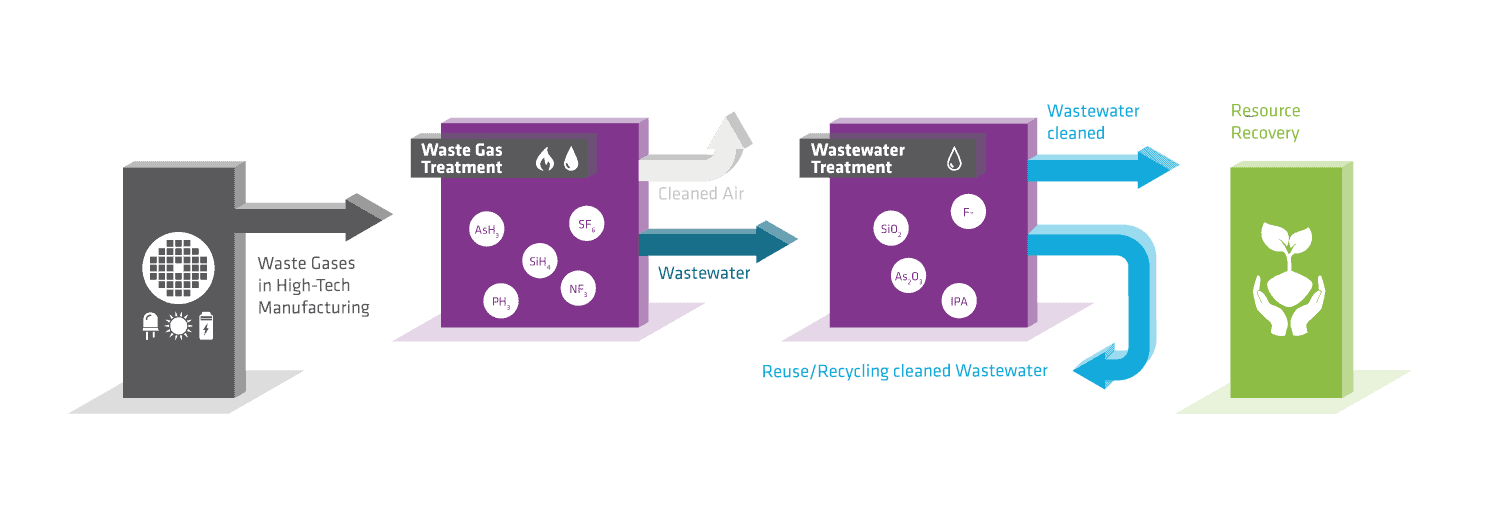

In many production procedures of the high-tech industries — such as etch, CVD and epitaxy processes — critical gases are used and waste gases produced which need to be treated directly. These waste gases, considered greenhouse gases, are toxic and/or highly flammable and very often pose a significant risk to production facilities and the environment.

By combining and transporting different gases into fab’s central waste gas system, entrained particles can clog the transport pipes.

In addition, highly flammable or explosive gas mixtures can be produced, which in extreme cases have already led to the total loss of entire production facilities.

To eliminate such risks, we at DAS have developed systems that treat waste gases directly at the point of origin (point-of-use) — burn/wet systems, wet scrubbers and electrostatic filters. The result is a particle-free, harmless gas mixture that can be released via exhausts. We also take care of scrubbing liquids, and if desired, treatment of wastewaters from wet-processes such as etching and planarization.

Dangerous Process Gases Require modern Waste Gas Solutions

In the semiconductor industry various process gases are used. These gases can pose a risk to the production facility, employees and the environment if they are not treated in the right way. DAS solutions work efficiently, fully automated and sensor-controlled for the best abatement results.

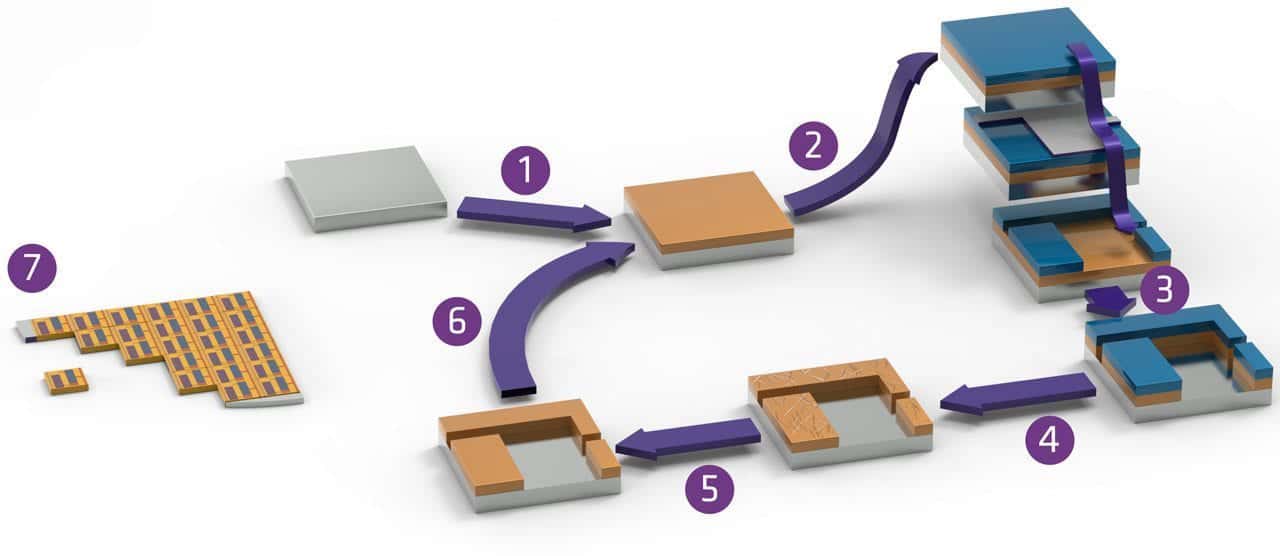

Flexible Point-Of-Use Solutions for Waste Gas Treatment

Since 1991 the POU equipment, developed and manufactured by DAS Environmental Expert GmbH, has mastered the task. DAS equipment can be used for practically all modern coating and etching equipment of the chip industry. Waste gases are treated safely and in an environmentally compatible way, with exhaust gases meeting the legal requirements. DAS technology is based on a flexible, integrated product concept. The smallest equipment fits into a closet of less than a 1 square meter footprint. DAS technology is fully automated and sensor-controlled and meets the highest certified safety standards.

From Wastewater Treatment to Ressource Recovery

In the semiconductor industry, waste water from various production and cleaning processes and subsequent waste gas treatment is generated. At DAS EE, we are specialists in the treatment of such wastewater. Whether you want to upgrade an existing wastewater treatment system or are planning a new plant, our experts will work with you to develop a customised solution that meets your needs and exceeds your expectations.

Centralised, Semi-Centralised & POU Systems

Every customer has individual requirements for their wastewater treatment plant. These have a significant impact on the design, technology, location and size of the plant. We offer centralised, semi-centralised and point-of-use systems, allowing our customers to choose the approach that best suits their specific needs. In addition, the modular design of our system components means that our DAS EE wastewater plants can be largely prefabricated and delivered to their place of use in an installation-friendly manner.

Our portfolio for the semiconductor industry includes among others

- Removal of organic contaminants, measured as chemical oxygen demand (COD) and biochemical oxygen demand (BOD), from wastewater

- Removal of heavy metals or other toxic compounds

- Treatment of chemical mechanical polishing/planarisation (CMP) waste water

Treatment of silicon waste

- Treatment and polishing of waste water containing fluride and arsenic

- Treatment of isopropyl alcohol (IPA) or other volatile

organic compounds (VOCs) - Reuse of treated wastewater (water recycling)

- Recovery and recycling of valuable metals from

wastewater

Semiconductor Manufacturers produce environmentally friendly through combined Waste Gas and Waste Water Treatment

DAS EE offers a comprehensive and well thought-out portfolio for semiconductor manufacturers. With our systems for waste gas abatement and water treatment, we have been ensuring for many years that chip production goes hand in hand with high demands on the protection of people and the environment. We are very familiar with the highest requirements for purity, reliability and safety, because companies in the semiconductor industry have been among our most important customers since the company was founded.

Sustainable Development Goals

We support the high-tech industry in implementing sustainability and green production — in line with the Sustainable Development Goals set by UNESCO.

Your contact for all topics in the field of the semiconductor industry

Dr. Christian Kuhne

Director Sales Global