Efficient Wastewater Plant Applying E‑Plate Heat Exchanger

Heat transfer from wastewater to process Water – wastewater heat exchangers ensure the reliable operation of a wastewater treatment plant and enable the recovery of heat from the wastewater stream.

The E‑Plate heat exchanger offers many advantages compared to conventional systems and represents an efficiency-increasing solution for solids-laden wastewater.

Many companies need hot process water in their production processes. An innovative system from Dresden (Germany) based DAS Environmental Expert GmbH now enables heat transfer from wastewater to process water. This helps to optimise the temperatures in the water flows, which significantly increases efficiency with regard to both energy usage and wastewater treatment.

Wastewater Heat Exchangers in the Paper Industry

Schumacher Packaging GmbH gained experience with this type of heat exchanger in its plant in Schwarzenberg. The owner-run, medium-sized company specialises in tailored packaging solutions using corrugated and solid board.

Schumacher Packaging GmbH is a cardboard producer in Schwarzenberg in the Ore Mountains in Germany. Their operation involves reprocessing used paper. The process requires a very large volume of water, drawn from a river, the Grosse Mittweida. In winter, the incoming water is relatively cold, arriving at a temperature of approx. 5°C. It undergoes a preliminary cleaning process and then has to be brought up to temperature using external sources of heat.

Schumacher Packaging GmbH has now increased the capacity of the paper machine. This also resulted in an increase in the process temperature to up to 55 degrees Celsius, which is much too high for the biological wastewater treatment to follow. The microorganisms die if the water is too hot. The result: the sewage treatment plant would no longer work at these temperatures. To prevent damage to the river, an official upper temperature limit of 30 degrees Celsius is also in place for discharging wastewater.

This is why Schumacher Packaging GmbH was looking for a sophisticated solution for cooling the wastewater so as to ensure the continued reliable operation of the biological wastewater treatment system and to allow the recovered thermal energy to be used to pre-heat the cold water from the river.

Heat Transfer with Minimum Loss of Pressure and Low-cost Maintenance

The conditions for the use of the heat exchanger on the customer’s premises were rather demanding:

- It had to tie into the existing gravity pipeline with minimum loss of pressure, and

- Be not susceptible to fouling + blockages → low-maintenance

The conventional heat exchanger designs were therefore unsuitable for the case in hand.

Construction Forms of Conventional Heat Exchangers

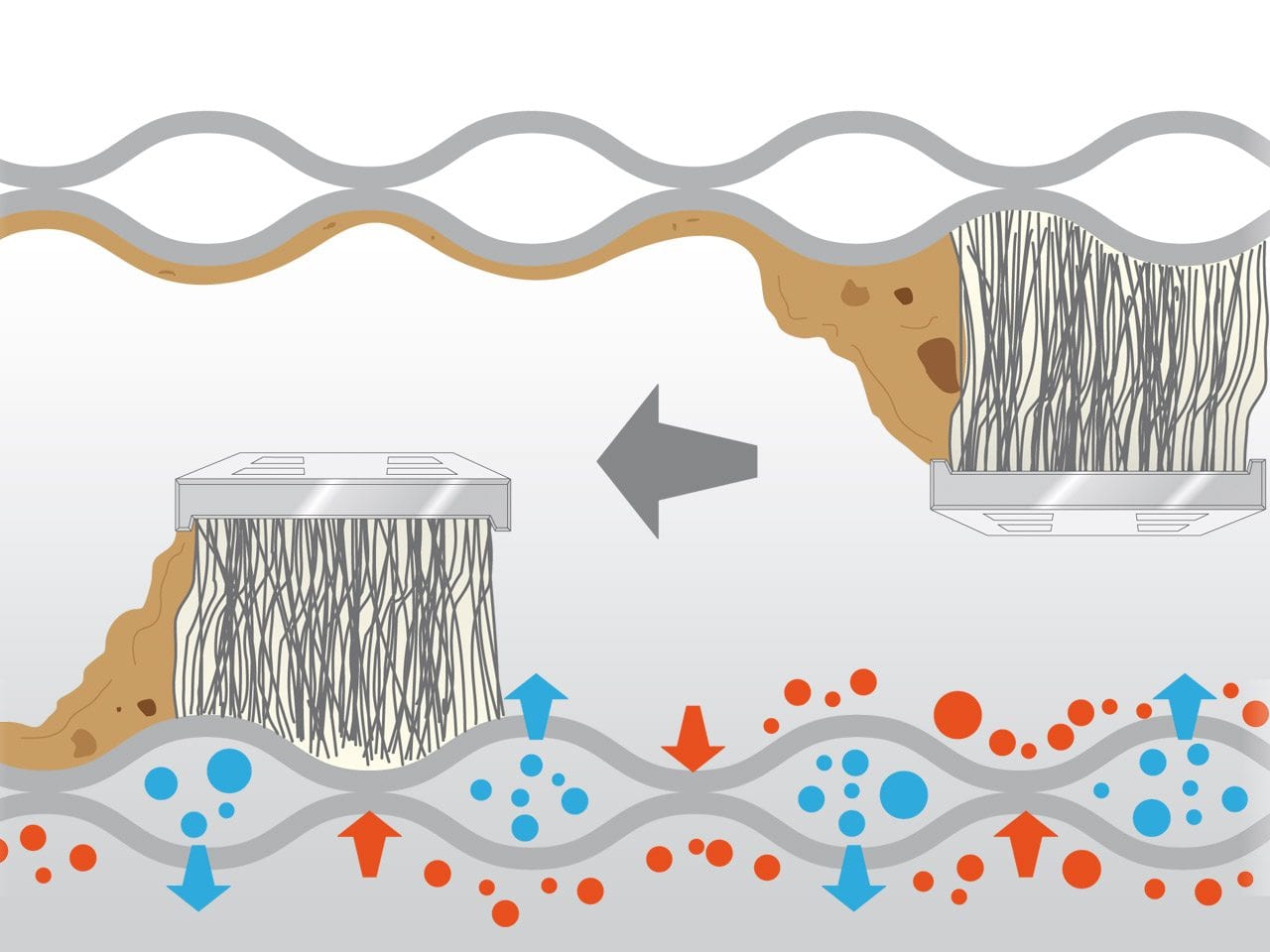

For decades now, conventional heat exchangers have seen successful and effective use for applications in many fields. However, to date there had been no satisfactory technical solutions identified in the wastewater sector. In contact with the actual wastewater, transfer surfaces foul up relatively quickly, leading to the creation of a bio-film which grows rapidly if the equipment is not cleaned regularly.

This process is termed fouling and leads to a reduction in heat transfer performance and therefore a drastic deterioration in the level of system effectiveness. Consequently, with standard equipment the transfer surfaces must be cleaned using a complex CIP (cleaning in place) process or opened up and — in the case of plate heat exchangers — even dismantled to allow the subsequent extensive cleaning to take place.

The result of mechanical processes is frequently less than adequate cleaning. The reason for this poor result is, for example, that the water jet cannot access all of the areas it should in the course of internal high-pressure cleaning, especially with larger heat exchangers.

Self-cleaning Heat Exchangers for Wastewater

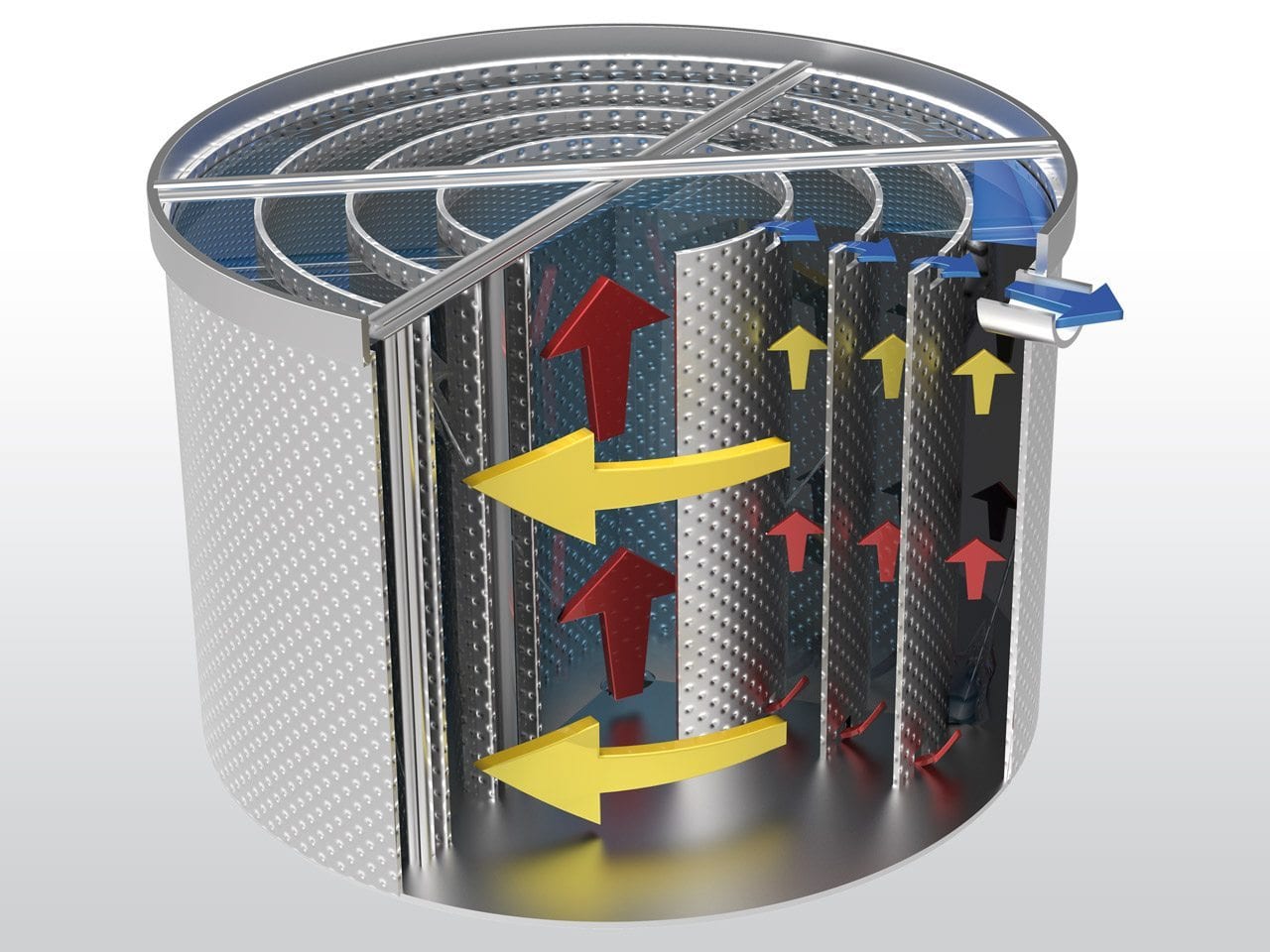

The solution identified for Schumacher Packaging is based on a heat exchanger with a constantly rotating brush system and what are termed thermoplates. This reduces fouling to a minimum and optimises heat transfer performance. The rotating brushes not only ensure that the heat transfer surfaces are kept clean at all times, but also promote a high flow speed and with this a higher level of heat transfer.

The rotary movement of the brushes also results in the wastewater circulation following a spiral path. This produces the effect of a counter flow heat exchanger. This construction principle permits installation in the discharge from existing sewage treatment plants without the use of additional pumps to increase the pressure. Extensive metering and regulation equipment is also rendered unnecessary.

The Principle on which the Wastewater Heat Exchanger Operates

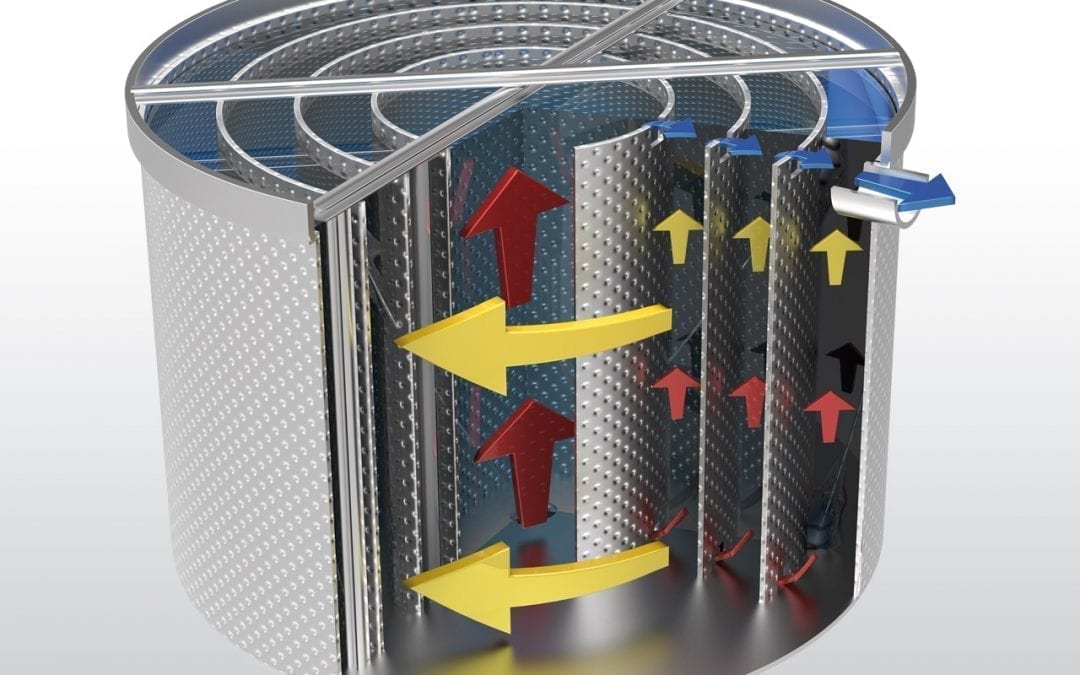

The (clean) cooling water is distributed evenly over all of the thermoplates and within these plates flows once through the heat exchanger, following a ring-shaped path. Thermoplates consist of two metal heat exchanger plates joined together completely at the edges and by means of spot welds on the flat area. The metal plates welded in this way are then hydraulically expanded and provided with connecting points for the cooling water inlet and outlet.

For permanent cleaning by means of a rotating brush system to be possible, these thermoplates must be shaped into rings. A number of these rings of increasing diameter are inserted inside each other and connected to a container. The outermost thermoplate doubles as the outer wall of the container.

The fouled wastewater is fed into the heat exchanger from below and flows upwards between the thermoplates and through the container, to be channeled off at the top. The rotary movement of the brushes also sees the wastewater circulation following a spiral path (spiral heat exchanger). This produces the effect of a counter flow heat exchanger.

Installation Upstream of the Wastewater Treatment System at Schumacher Packaging in Schwarzenberg

In the case of Schumacher Packing, there were two heat exchangers installed. They can be operated individually, in series or in parallel, thus guaranteeing a high degree of flexibility in the operation of the system. This is important because if the wastewater is too cold this will also have a detrimental effect on the metabolism of the micro-organisms in the biological wastewater treatment system.

Performance Data for the Installed Heat Exchangers

| Kategory | Output |

|---|---|

| Heat output | 1 MW |

| Flow rate — wastewater side | 65 m³/h |

| Pressure loss — wastewater side | 55 m³/h |

| Pressure loss — wastewater side | 0,01 bar |

| Pressure loss — cooling water side | 0,40 bar |

These heat exchangers are already in use in the following sectors and fields

Advantages over conventional heat exchangers

- Permanent self-cleaning

- Suitable for wastewater containing solids

- Low level of pressure loss

- Simple to inspect

- High turbulence rates due to rotating brushes, resulting in good heat transfer

Apart from the energy-saving effect from the direct recovery of heat, the use of heat exchangers of this type opens up new possibilities for the dimensioning and operation of wastewater technology.

Wastewater Heating for Anaerobic Reactors

The primary point to be made here is the possibility of using anaerobic reactors operated advantageously at a temperature of between 35 and 38°C. Anaerobic biological stages are characterised by the fact that harmful materials are broken down in the absence of any supply of oxygen.

If the wastewater in question is not at the required temperature, then with a clever combination of heat recovery in the outlet and simultaneous pre-heating of the wastewater which is below the desired temperature, with only a minimum outlay on energy it is possible for the optimum temperature for the anaerobic reactor to be maintained.

Anaerobic wastewater treatment is particularly suitable for highly-contaminated industrial wastewaters. The advantages over aerobic processes — i.e. undertaken with the aid of oxygen — are in particular the considerable lower electricity requirement, the reduced amount of residual materials generated (excess sludge), high throughput levels and therefore compact construction designs, and finally the generation of biogas.

A proportion of the biogas can be used for maintaining the optimum operating temperature in the anaerobic reactor. The majority of this biogas can be used for both heating purposes and also for conversion into electricity in block-type thermal power stations.

Enhanced Performance for Aerobic Wastewater Technology

Even aerobic biological stages can be brought up to the optimum operating temperature with the aid of a heat exchanger installed upstream. An increase in the performance of existing systems can be achieved in this way. When new biological sewage treatment plants are being constructed, they can now be made smaller and more compact in their design and dimensioning.

For communal sewage treatment plants, energy efficiency is likewise an important aspect. Accordingly, for some time now there have been attempts made to recover the heat contained in wastewater. Until now, a number of factors have been preventing this being achieved with large-scale technology.

- Rapid build-up of a coating on the transfer surfaces.

- The rapid decrease in performance and high maintenance costs associated with this.

- Additional pumping equipment to compensate for the pressure loss.

This last point is of particular importance as in the discharge outlet of many sewage treatment plants (both industrial and communal), the height difference between the discharge from the wastewater treatment system and the surface level of the outfall is very slight.

Additional Wastewater Technology Rendered Largely Superfluous

The installation of these additional pumps would have the effect of considerably reducing (or even nullifying) the beneficial effect of enhanced energy efficiency from the recovery of heat. The pressure lost with conventional heat exchangers is caused by the high flow rates required for effective operation. At the same time, the flow channels are kept as small as possible, in order to achieve a high level of heat transfer. This in turn leads to more rapid blocking and ever greater losses of pressure. Normal values for pressure loss are around 0.5 bar to 1.0 bar — corresponding to 5 to 10 metres in terms of differential head.

It is in this point that the system of self-cleaning heat exchangers presented here sets itself most clearly apart from all other systems. The typical value for pressure loss is around 0.01 bar — corresponding to a differential head of 0.1 metre.

Suitable for Wastewater Containing Solids

In summary it can be stated that these heat exchangers represent an efficiency-enhancing solution for wastewaters containing solids, where the wastewater is too cold or too warm or if the sewage treatment system is operating inefficiently.

In the case of Schumacher Packaging GmbH, the installation of the heat exchanger produced a saving of 40% of the volume of natural gas previously required. This saw the investment paying for itself within the first year

Your contact person for all questions on wastewater treatment

Mirko Heinze

Chief Operating Officer Water Treatment