Clever Solutions for energy-efficient Wastewater Treatment Plants

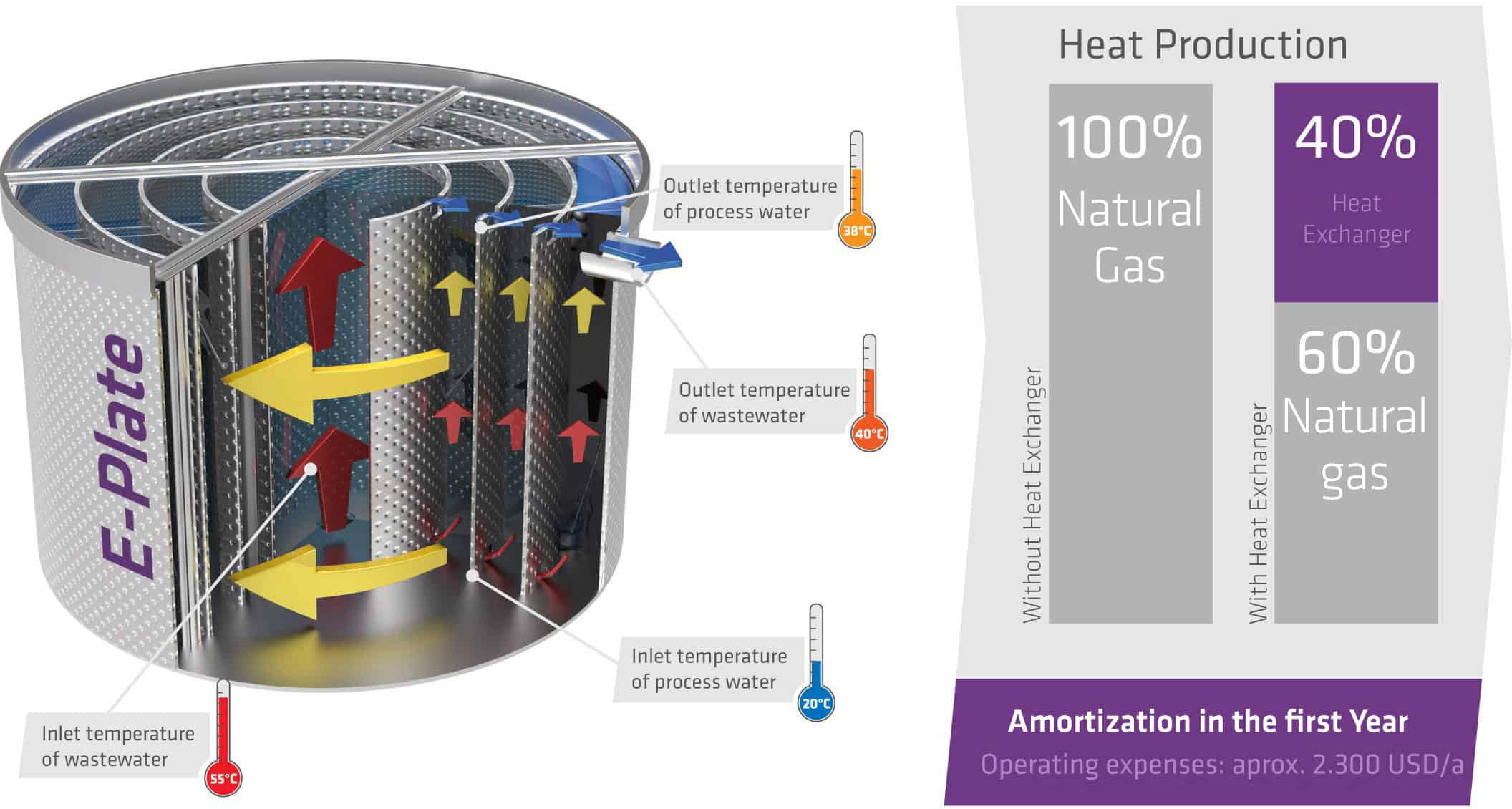

With DAS’ technical solutions, it is possible to design processes in an economical and resource-saving way. The heat exchanger “E‑Plate”, for example, uses waste heat from wastewater for optimal temperature control of colder fresh water and the ejector aerators used by DAS in MBBR or activated sludge plants ensure energy-efficient aeration and mixing.

Reduce your Operating Costs quickly & effectively

The wastewater of many companies is too warm to be discharged uncooled into wastewater treatment plants. For example, paper mills, large-scale laundries or food industry companies have to go to great lengths to comply with upper temperature limits.

This is because both the biological processes in wastewater treatment plants and surface waters such as lakes and rivers into which the treated wastewater is discharged are temperature-sensitive. Where processes in the plant such as nitrification and the anerobic stage require a water temperature of around 30 degrees Celsius, the solubility of oxygen in the water in surface waters decreases as the temperature rises, which is why strict regulatory limits must be observed for discharge.

In order to cool down wastewater that is too hot to the required temperature, it is therefore often mixed with ambient water in the inlet to the wastewater plant. However, the greater hydraulic throughput associated with this leads to higher wastewater costs. In addition, this requires the plant to be larger in size than is required for effective treatment – resulting in both higher construction costs and higher operating costs. Cooling towers are not an optimal alternative: they lead to permanent noise emissions, further displacement of water into the atmosphere and require a lot of space.

Accordingly, the cooling process is costly – and this despite the fact that in many companies production water that is too cold has to be heated in an energy-intensive manner at the same time.

Heat recovery from wastewater with the DAS heat exchanger E‑Plate

YouTube is a service of YouTube LLC, a subsidiary of Google Inc, USA. You can find more information on data processing through this in our privacy policy. If you would like to watch this video, you also consent — revocable at any time — to the transfer of your data to the USA and the associated data processing in accordance with Art. 49 (1) a) DSGVO.

DAS offers the plate heat exchanger “E‑Plate”, which uses waste heat from wastewater to temper water that is too cold. This allows our customers to save significant amounts of energy. Our thermal plate heat exchanger requires little space, is robust and low-maintenance: E‑Plate cleans itself with the aid of an optimized brush system. This makes it optimal for use even with heavily contaminated wastewater.

Our heat exchanger consists of ring-shaped, double-walled stainless steel plates through which the cold fresh water flows. The wastewater is fed into the heat exchanger from below and flows upward through the tank. The continuously rotating brush system not only keeps the plates clean, it also spirals the wastewater and provides a high flow velocity. This significantly increases the performance of the heat exchanger. The cooled wastewater is finally discharged at the top of the heat exchanger. This results in the effect of a countercurrent heat exchanger. This design principle allows the E‑Plate to be installed in the outlet of existing wastewater treatment plants without the use of additional booster pumps. Complex measurement and control technology is also not required. Thus, for many of our customers, the plate heat exchanger of DAS Environmental Expert GmbH proves to be an investment that pays for itself within a very short time.

Best possible circulation performance with 2/3 less energy consumption — the DAS ejector aerators

For efficient aerobic degradation of oxidizable substances in wastewater treatment plants, oxygen must be supplied. Aeration measures usually improve both the operational safety and the degradation performance of the system. Aeration ensures a rapid transfer of oxygen from the gas phase into solution. This can be achieved by increasing the oxygen concentration in the air mixture or by using an aeration process that produces an optimum bubble size. However, a lot of energy is often required for optimal aeration and mixing in biological wastewater treatment systems. Aeration systems typically account for up to two-thirds of the total energy costs of a wastewater treatment plant.

Effectively prevent deposits

Ejector aerators not only enable a high oxygen input. These systems for wastewater aeration can be used at the same time to mix wastewater and sludge as well as to prevent deposits in the basin. A special nozzle design effectively prevents sludge accumulation at the bottom and keeps solids in suspension – regardless of the amount of oxygen introduced.

This makes ejector aerators ideal for use in MBBR or activated sludge plants. They ensure efficient oxygen supply – and reduce the energy requirements of the overall plant.

Ejector aerators are based on the operating principle of a jet pump: flowing water serves as the motive medium and creates a suction via which air is drawn in. This air is supplied via suction pipes, mixed with the water flow and directed into the wastewater tank. A blower is not necessary for this. The jet pump works by flow alone, without a mechanical drive. It is therefore very robust and requires little maintenance.

Your contact for all questions on the subject of “Clever solutions for energy-efficient wastewater treatment plants”.

Mirko Heinze

Chief Operating Officer Water Treatment