Point-of-Use Waste Gas Treatment with ESCAPE (burn/wet)

DAS Environmental Expert developed the ESCAPE product family based on the burn/wet technology. The system treats different process waste gases of the semiconductor and photovoltaics industry. The media supply of the systems can be carried out variably.

Waste Gas Treatment – ESCAPE

Treatment of Waste Gases with ESCAPE

All ESCAPE systems have a small footprint with service and maintenance access from the front and back. Installation is quick and easy and does not require specialised equipment. Operation costs and general safety can be optimised with a process tool interface.

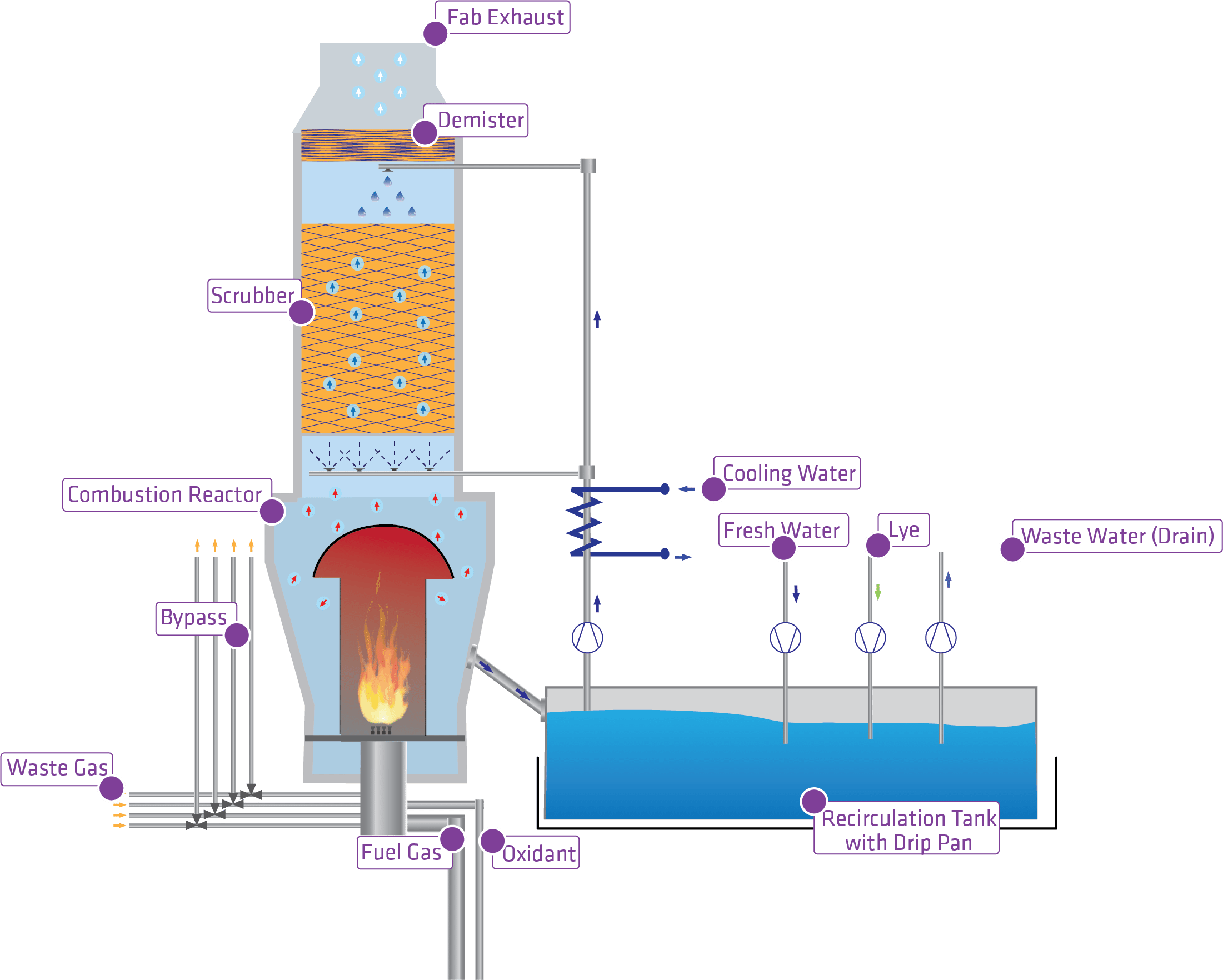

Operating Principle of ESCAPE

Hazardous substances of process waste gases are abated directly from where they originate (Point-of-Use). Waste gases are fed into a ring-shaped burner apparatus. Depending on the chemical composition of the waste gases, various reactions take place (oxidation, reduction, pyrolysis).

In the subsequent scrubbing process, soluble, gaseous and solid compounds generated by combustion are absorbed and cooled down by a suitable scrubbing liquid. The immediate scrubbing neutralises combustion products such as hydrogen halides. With the application of ESCAPE within a holistic abatement concepts, manufacturers in the high-tech industry will meet the strict standards of the German air pollution law (TA Luft).

ESCAPE DUO — Waste Gas Treatment with Backup-Function

ESCAPE DUO is our well-established standard version designed with a double-reactor offering two scrubbing systems that can operate simultaneously. It is optimised for up to four independent inlets. In case of malfunction or maintenance on one reactor, the other backs up the treatment of all waste gases (internal back-up), which ensures the equipment’s near 100 % uptime. The system runs with different fuel gases and washing liquids. It is characterized by low water consumption through a closed-loop design.

Specifications

- Up to 2 independent waste gas and backup lines per reactor

- Operation time > 99% through backup function

- Second reactor allows uninterrupted operation during maintenance

- Runs with different fuel gases and scrubber liquids

- Low water consumption through closed-loop design

- Available in two sizes

Technical Data

- Dimensions (W x D x H): 1650 mm x 675 mm x 1800/2070 mm

- Access to maintenance area on front and back side

- Gas entry: max. 4x DN25 or DN40

- Gas outlet: max. 2 x DN100

Further ESCAPE Products

ESCAPE INLINE

ESCAPE INLINE is our basic system, optimised for up to four independent inlets. It runs on diverse fuel gases and scrubber liquids. As an alternative to the scrubber liquid’s feed-through-system the reactor can be equipped with a water-conserving closed-loop design.

Technical Data

- Dimensions (W x D x H):

- 855 mm x 675 mm x 1800/2070 mm

- Access to maintenance area on front and back side

- Gas entry: max. 4 x DN25 or DN40

- Gas outlet: DN100

Configuration Options of ESCAPE

The following equipment options are available for all ESCAPE systems:

- Power Supply: 3 x 400 V/50 Hz or 3 x 208 V/60 Hz

- Fuel Gas: NG, LPG, H2

- Oxidant: O2, CDA

- Heated feed lines and inlets

- Process-Tool-Interface

- Signal Tower

- Drip Pan

- Earthquake Safety Kit

- Monitoring

- SEMI S2 certification