UPTIMUM - Efficient Waste Gas Treatment of CVD Processes

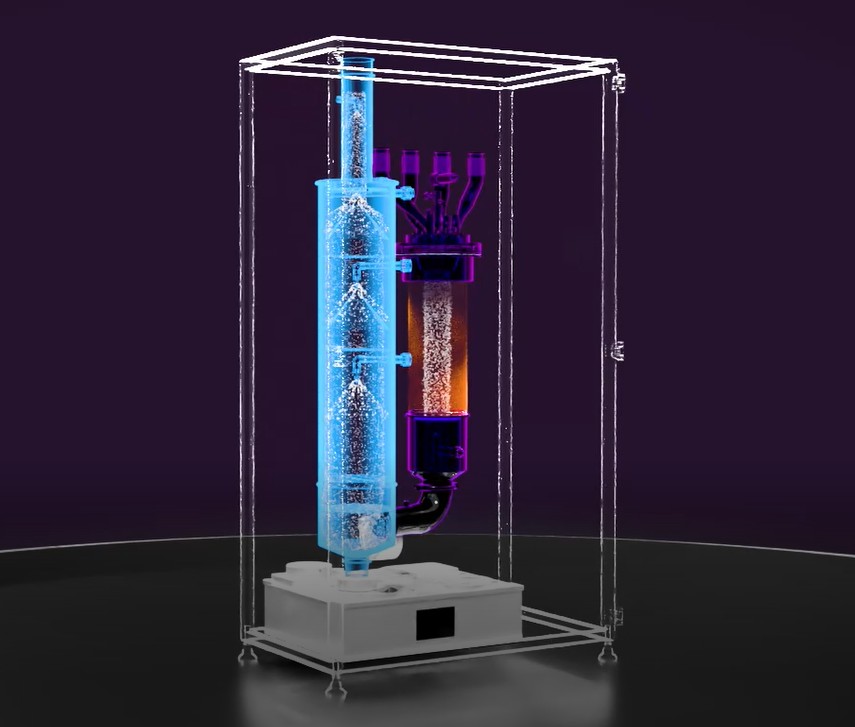

UPTIMUM is part of the burn-wet technology portfolio of DAS Environmental Experts. The system is specifically designed to meet a higher uptime demand in specific CVD processes.

UPTIMUM – Powerful Solutions at the Point of Use

All UPTIMUM systems have a small footprint with service and maintenance access from the front and back. Installation is quick and easy and does not require specialised equipment. Operation costs and general safety can be optimised with a process tool interface.

Efficient treatment of industrial processes with UPTIMUM

UPTIMUM is optimised for up to six independent gas inlets from CVD processes in a wide range of industrial sectors. Various fuel gases and washing liquids can be used. UPTIMUM PLUS is specially adapted to the requirements of thin-film silicon photovoltaic processes. This variant can dispose of higher quantities of H2 and NF3 (or F2) without compromising system availability.

Burn-Wet Technology for Safe Waste Gas Treatment

The compact burn-wet combination from DAS Environmental Experts is based on decades of experience in waste gas treatment. Process gases are oxidised, reduced or pyrolysed in a ring-shaped burner, depending on their composition. Subsequent wet scrubbing reliably cools and binds the resulting compounds. This point-of-use technology enables the safe and efficient treatment of industrial waste gases – including those containing fluorine compounds, ammonia, silane or hydrogen – and is used worldwide in the semiconductor industry.

Optimise Your Waste Gas Treatment with UPTIMUM

UPTIMIUM is designed for broad applicability across a wide range of CVD processes in various industries.