Fine Dust in the Industry

Fine dust plays an important role in industry not only in terms of occupational safety: during industrial processes, any waste gases produced must be reliably treated, and the fine dust they contain must be safely removed. The high-tech industry in particular relies on solutions from DAS Environmental Expert GmbH.

Industry is one of the largest emitters of fine dust

From energy production through to logistics, production processes and waste treatment, industrial operations make a large contribution to air pollution. The use of solvents, for instance in the chemical and mineral industries, and production processes in the high tech industry are examples of fine dust sources in industry.

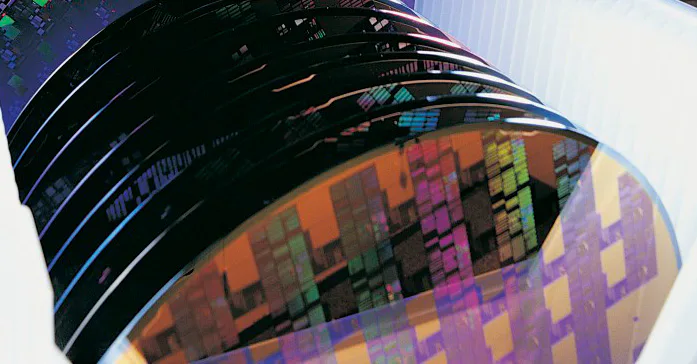

Fine dust sources in the high tech industry

In the semiconductor sector, the cutting of wafers using lasers in the back-end section is one example of a significant source of fine dust. Dust particles can also be produced when disposing of process waste gases using thermal processes (incinerators), especially following coating processes such as epitaxy processes, or when coating large surfaces as is the case when manufacturing solar cells or flat screens. In the absence of further measures, they enter the waste air system where they can cause clogging, for example, and could therefore force an entire plant to halt operation. When fine dust is released into the atmosphere, it is also a risk for health and the environment. In factories, great care is taken to ensure that no dust particles enter critical areas, such as cleanrooms, as fine dust can damage both equipment and products such as wafers.

Fine dust separation processes

Fine dust poses a risk for men and machines. For industrial processes in particular, waste gases that are produced must be dealt with reliably and safely, and the fine dust they contain needs to be separated. Different processes are used for this:

Cyclone separators, electrostatic separators, wet separators and filtering separators. To separate fine dust, in particular PM2.5 fraction and ultrafine particles, electrostatic separators or filtering separators are usually used. Cyclone separators, on the other hand, are better suited to coarse particles.

Electrostatic filters use an electric field to remove particles, aerosols and condensates from the waste air flow. Both fine and very fine dust, as well as condensable organic compounds, are thus reliably and efficiently removed from the waste gases.

Flue gas scrubbers bring the waste gas flow into contact with a scrubbing liquid that binds and partially dissolves the particles it contains. The resulting mixture is divided and separated from the waste air flow and the scrubbing liquid is purified.

In filtering separators, the waste air flows through a filter element, usually from outside in. The filtrate then settles on the filter medium, forming what is known as a filter cake – a layer of dust that needs to be removed regularly.

Solutions for Different Types of Fine Dust

Find out on the following page which technical solutions can be used in practice.