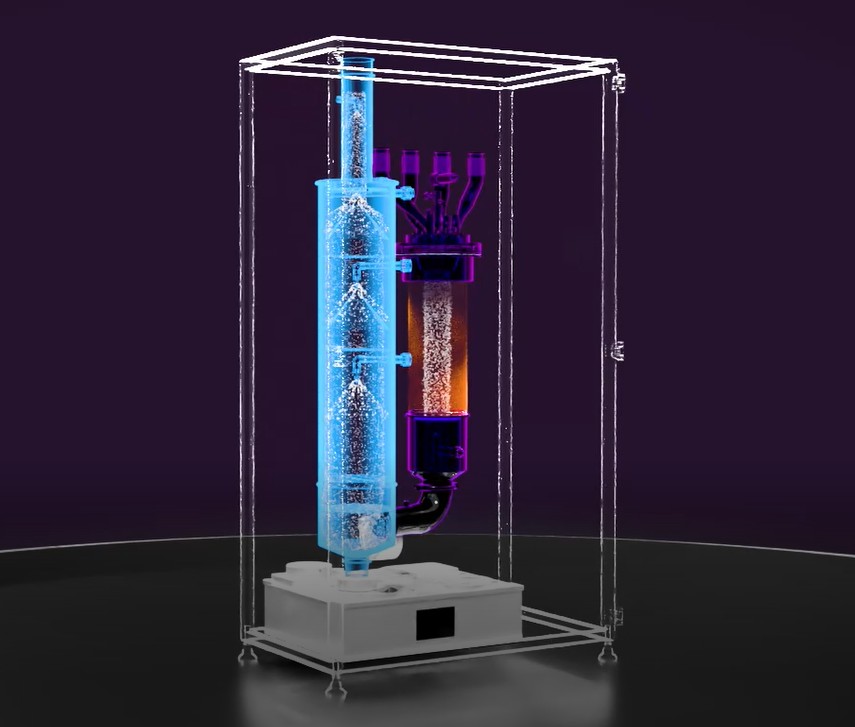

Point-of-Use Waste Gas Treatment with ESCAPE DUO (Burn-Wet)

Compact high-performance system for semiconductor and photovoltaic processes

ESCAPE DUO – Modular Burn-Wet Systems for Safe and Efficient Process Gas Cleaning

Treatment of Waste Gases

The ESCAPE product line is the basis of our point-of-use burn-wet technology, which has been proven on the market for more than 25 years. The waste gas scrubber (burn-wet) is used very flexibly and customised to clean almost all process gases generated in the semiconductor and photovoltaic industries.

The space-saving systems can be configured in different heights and are also easy to maintain without special tools! The media supply can also be varied. An optional process coupling increases safety and reduces operating costs – for efficient and reliable exhaust gas treatment directly at the point of use.

Efficient Treatment of Industrial Processes with ESCAPE DUO

The manufacture of high-performance high-tech products such as microchips, photovoltaic modules, flat screens and light-emitting diodes involves highly complex, multi-stage production processes. These processes generate waste gases in various sub-steps, which must be disposed of directly at the point of use.

CVD – Chemical Vapor Deposition

Chemical vapour deposition (CVD) involves chemical reactions that produce thin layers on substrates, e.g. made of silicon nitride or polysilicon. DAS Environmental Experts offers efficient systems such as ESCAPE, UPTIMUM, STYRAX and LARCH for the safe waste gas treatment of these CVD and MOCVD processes.

Etch

Etching involves the targeted removal of materials using chemical substances – for example, in semiconductor manufacturing. DAS Environmental Experts reliably treats the fluorine-containing waste gases produced during this process using ESCAPE and STYRAX systems based on burn-wet technology.

Burn-Wet Technology for Safe Waste Gas Treatment

The compact burn-wet combination from DAS Environmental Experts is based on decades of experience in waste gas treatment. Process gases are oxidised, reduced or pyrolysed in a ring-shaped burner, depending on their composition. Subsequent wet scrubbing reliably cools and binds the resulting compounds. Depending on the DAS abatement system, the process design may differ.

This point-of-use technology enables the safe and efficient treatment of industrial waste gases – including those containing fluorine compounds, ammonia, silane or hydrogen – and is used worldwide in the semiconductor industry.

Optimise your Waste Gas Treatment with ESCAPE DUO

Rely on dependable burn-wet technology – individually configurable for your production requirements.