LARCH – Burn-Dry System (Pyrolysis)

Point-of-Use Treatment of Waste Gases from MOCVD Processes in the LED and GaN Industry

LARCH Burn-Dry Systems

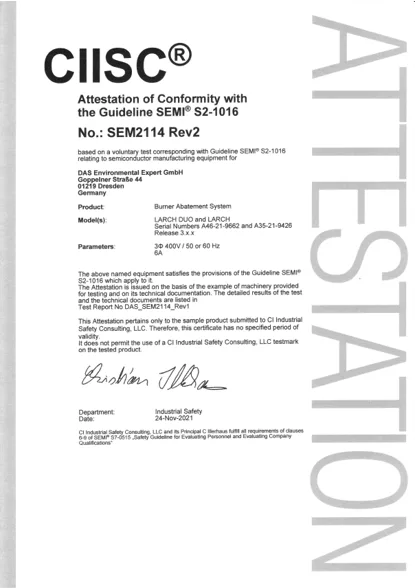

LARCH systems were developed by DAS Environmental Experts specifically for the treatment of waste gases from MOCVD processes for LED, μLED, GaN, and waste gases from EUV processes at the point of use.

The treatment combination of oxidation und pyrolysis extends DAS´ technology portfolio in a sustainable way. Low investment and operating costs, a simple, robust design and low environmental impact (no CO2 emissions, minimum NOx emission) characterize LARCH. No fresh water is required and no waste water is produced. Current installations demonstrate maintenance intervals of more than six months. Maintenance access is possible from two sides. Operation costs can be optimized with a process tool interface. By the application of heat exchangers, the process gas heat can be used for other production areas.

LARCH – Burn-Dry Systems for Efficient Treatment of Industrial Processes

LARCH

LARCH is our Point-of-Use waste gas abatement system. It is capable of treating large flows of hydrogen and ammonia as well as small flows of metal-organics and silan, which are typically found in common MOCVD and EUV processes. Characteristics of LARCH include low investment and operating costs, a simple and robust design, and a low environmental impact: no CO2 emissions, minimal NOx emissions and no wastewater. LARCH systems can also handle high N2 flows without any problems. The maintenance interval exceeds six months.

LARCH PLUS

LARCH PLUS is our most recent addition of the LARCH Point-of-Use product family. It was launched to satisfy the GaN and EUV capacity hunger and is capable of treating large flows of hydrogen and ammonia as well as small flows of metal-organics and silan. LARCH PLUS can dispose of more waste gases with lower emissions and a slight increase in footprint. Characteristics of LARCH PLUS include low investment and operating costs, a simple and robust design, and a low environmental impact: no CO2 emissions, minimal NOx emissions and no wastewater. LARCH PLUS systems can also handle high N2 flows without any problems. The maintenance interval exceeds six months.

Optimise Your Waste Gas Treatment with LARCH

Optimised for point-of-use treatment of waste gases from MOCVD processes in the LED and GaN industries.