Point-of-Use Waste Gas Treatment with STYRAX

Burn-Wet and Plasma-Wet Systems for Processes in the Semiconductor Industry

STYRAX – Waste Gas Treatment for Demanding High-Volume Processes

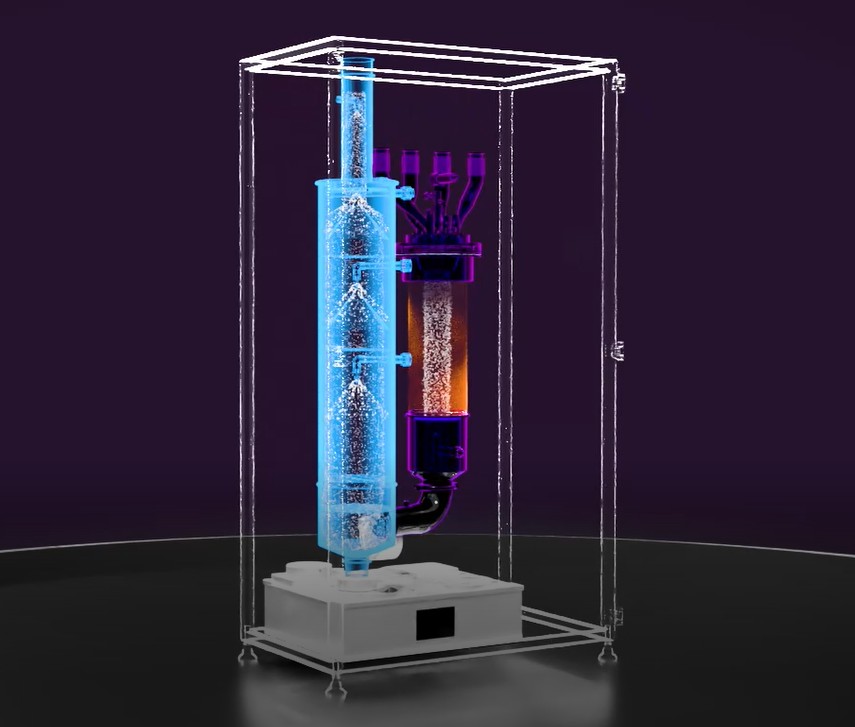

STYRAX is DAS's high-performance product family for demanding high-volume manufacturing environments. The product family includes point-of-use burn-wet and plasma-wet systems with a particularly compact footprint.

It was developed specifically for process gases from CVD, oxide/poly/metal etching, epitaxy, GaN, MOCVD and LED manufacturing. STYRAX is characterised by high efficiency with low environmental impact and achieves excellent destruction and removal efficiency (DRE), for example > 95% for CF₄. Thanks to its high capacity for CVD gases such as H₂, SiH₄, TEOS and many more, as well as comprehensive safety measures, STYRAX protects the environment, health and equipment alike.

Efficient Waste Gas Treatment of Industrial Processes with STYRAX

STYRAX Burn-Wet

The development of the STYRAX product family bases on two significant aspirations for modern waste gas treatment: Improved PFC abatement and Reduced Maintenance Intervals. The scrubbing stage is optimized for HF. Water and/or lye consumption are minimized. A special inlet design prevents clogging. Further options are available to improve maintenance intervals in other processes.

STYRAX Plasma-Wet

The STYRAX plasma-wet systems set new standards in waste gas treatment by using electrical energy directly and highly efficiently. Thanks to the integration of a powerful DC plasma torch and a 15 kW power supply, optimum energy yield is achieved. The proven reactor design and washing stage have been retained, making the STYRAX plasma scrubbers just as reliable and easy to maintain as their natural gas-powered predecessors. The footprint remains compact. At the same time, energy consumption has been reduced by an impressive 50%!

Burn-Wet Technology for Safe Waste Gas Treatment

The compact burn-wet combination from DAS Environmental Experts is based on decades of experience in waste gas treatment. Process gases are oxidised, reduced or pyrolysed in a ring-shaped burner, depending on their composition. Subsequent wet scrubbing reliably cools and binds the resulting compounds. This point-of-use technology enables the safe and efficient treatment of industrial waste gases – including those containing fluorine compounds, ammonia, silane or hydrogen – and is used worldwide in the semiconductor industry.

Optimise Your Waste Gas Treatment with STYRAX

Rely on efficient burn-wet or plasma-wet technology for maximum DRE for e.g. CF4, SF6 or NF3 and low water consumption.