Burn-Wet Systems for Waste Gas Treatment

The combination of the two operating procedures burning & scrubbing in the smallest possible space allows a safe treatment of waste gases at the point-of-use.

Waste Gas Treatment in the Semiconductor Industry

The burn-wet technology is applied in a variety of DAS abatement systems treating different dangerous and harmful waste gases. In the semiconductor industry for example fluorine-compounds, ammonia, silane or hydrogen are used. Our compact solutions have a small footprint and are easy to maintain. Operation costs and general safety can be optimised with a process tool interface.

ESCAPE – Our Basic System for Process Waste Gas Treatment

The ESCAPE product line is the basis of our point-of-use burner-scrubber technology which is well-established for more than 25 years on the market. Gas Scrubber (burn/wet) offers flexible and customised applications for the abatement of almost all process waste gases in the semiconductor and photovoltaic industries. Media supply is variable.

STYRAX – Waste Gas Treatment for Waste Gases from Demanding CVD Processes

The STYRAX product family was specifically developed to manage demanding waste processes like CVD processes in the semiconductor and photovoltaic industry. Our application specialists configure the system, which is available as a burn-wet or plasma-wet system, to meet customer-specific requirements. In this way, media consumption can be adopted flexibly.

TILIA – Dual Reactor System with Internal Redundancy

TILIA is a compact solution for safely disposing of pyrophoric, fluorinated and toxic process gases in the semiconductor and solar industries. Its combination of combustion and wet scrubbing achieves maximum separation efficiency. Find out how TILIA could replace several of your conventional exhaust gas cleaning systems.

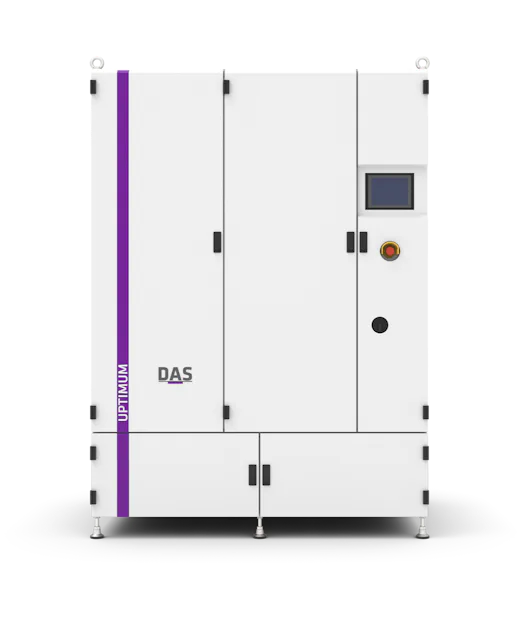

UPTIMUM – Optimized Waste Gas Treatment for High Tool Availability

The UPTIMUM product line has been designed for higher tool uptime especially in CVD processes in the semiconductor and solar industry. The product name UPTIMUM refers to the term “Uptime“ underlining the high availability of the burn/wet system. The tool can be applied to different applications.