Nitrogen Oxides (NOx) in the Semiconductor Industry

Basically, the semiconductor industry is one of the most resource-intensive industries in the world, with extensive environmental impacts in terms of energy and water consumption and waste production.

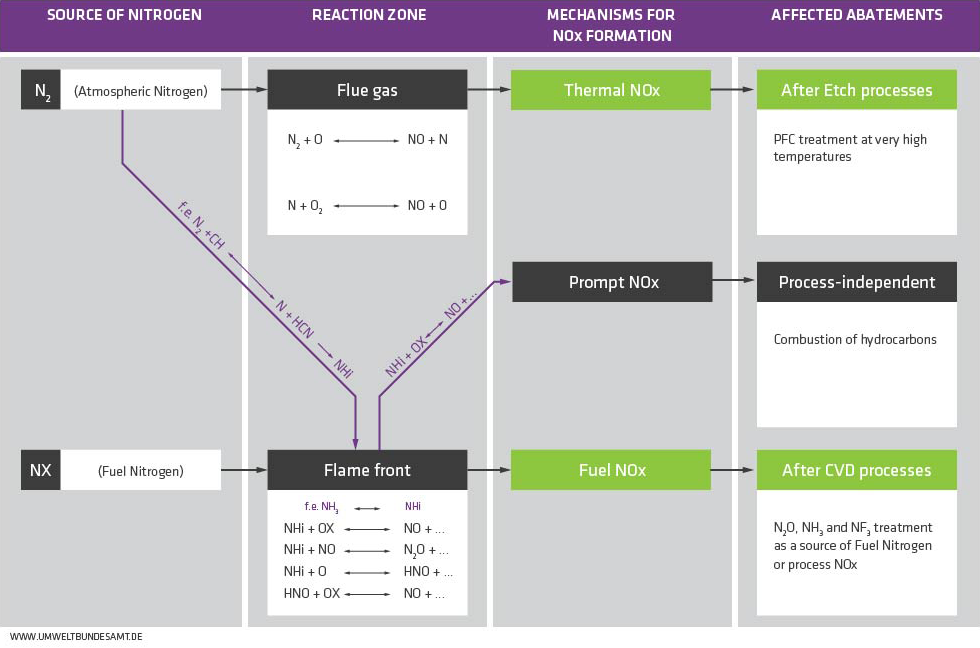

Nitrogen is generally used as a protective gas or purge gas in the processing of silicon wafers in clean rooms because the gas is extremely inert under normal conditions — but at high temperatures it can produce thermal nitrogen oxides (NOx). This mainly affects point-of-use incinerators that are used for the removal of perfluorocarbons (PFCs) after etching processes. The temperatures required in the reactor for the decomposition of PFCs promote the formation of NOx as a side effect.

In the semiconductor industry, nitrogen compounds are also required for the deposition of nitride layers, for example. Nitrous oxide is normally used to form oxynitride layers in the chemical vapor deposition (CVD) process. Nitrogen trifluoride (NF3) is used to clean CVD chambers not only in microelectronics production, but also in the production of thin-film screens and thin-film solar cells, and ammonia (NH3) is also used in the production of crystalline silicon solar cells.

The unreacted residues of these nitrogen-containing compounds are usually disposed of thermally together with other process gases and are therefore considered to be the source of the nitrogen oxide emissions that arise according to the fuel-NOx mechanism.

DAS Environmental Experts offers innovative solution for secondary exhaust gas purification

As an innovation leader in the semiconductor industry, DAS Environmental Expert GmbH (DAS EE) has developed TSUGA, a solution for secondary purification for NOx-generating exhaust gas cleaning systems, such as burn-wet systems. This approach is an efficient and reliable option for high-tech fabs and other industrial applications.

The TSUGA point-of-use solution removes NOx in the concentration range up to 4000 ppm (NO2, NO), fine dust (PM1, PM2.5, PM10) and particles in high exhaust gas flows up to 5000 slm (standard liters per minute). This means that several exhaust gas purification systems can be connected to one TSUGA.

The DAS solution for NOx and dust reduction combines state-of-the-art technologies: a highly efficient DeDust filter system and the selective catalytic reduction technology for DeNOx. More than 99% of the particles (including SiO2) are demonstrably separated in the DeDust stage. This filtration prevents clogging of the downstream components and the downstream catalytic converter and thus also ensures the best catalytic activity over a long period of time.

In the subsequent DeNOx stage, a technology is used that demonstrably converts NOx into nitrogen (N2) and water (H2O): selective catalytic reduction (SCR). Thanks to the SCR catalytic converter, a NOx reduction of more than 95% and emission values in the range of 5 ppm can be demonstrably achieved. State-of-the-art DeNOx catalytic converters are used in TSUGA. Ammonia (NH3), which is used for the reduction of NOx, is added automatically. Internal sensors ensure precise control and low overall media consumption.

With our design, we can ensure the efficient treatment of fluctuating NOx concentrations over a very long period of time and long-term catalytic activity. TSUGA works with minimal energy consumption by recovering more than 75% of the process heat.

Real-time monitoring is also integrated into TSUGA: The system is equipped with online measurement of NOx emissions. This enables optimized control of all relevant parameters and ensures TA-Luft and EPA conformity. The data generated is available for official requirements and documentation purposes. Access for operation and maintenance of the system is only from the front.

Waste Gas Treatment Abatement TSUGA

Post Combustion Waste Gas Treatment for NOx

DAS EE is your partner for the reliable and efficient treatment of nitrogen oxides (NOx).

No matter what your requirements are, our experts will find the perfect solution for you!

Contact & Consulting

Your contact person for all questions about efficient solution for reducing nitrogen oxide (NOx) emissions

Dr. Christian Kuhne

Director Sales Global