Our Portfolio for Point-of-Use Waste Gas Treatment

Abatement Concepts for Waste Gas Treatment

The treatment of industrial waste gases serves the protection of people and the environment as well as the stability of the production process. DAS Environmental Experts has dedicated itself to this task more than 30 years ago. Our abatement concepts are always customized and manufactured according to high industrial standards in Germany. Our worldwide service teams professionally support all systems installed. Due to our in-house R&D capacities at our Headquarters in Dresden/Germany

as well as in the innovation centers in Taiwan and the USA, we cooperate closely with our customers and adopt quickly to new innovation cycles. Our solutions comply with the highest quality and safety standards of the high-tech industry and meet the demanding requirements of the German TA Luft (Technical Instructions on Air Quality Control). All this makes DAS Environmental Experts one of the leading companies in its branch.

Our Waste Gas Treatment Portfolio at a Glance

Planning and Design of Customized Waste Gas Treatment Systems

DAS Environmental Experts partners with manufacturers, building designers and OEMs to develop and optimize waste gas treatment systems. Together we can identify innovative solutions with respect to safety, cost and energy saving as well as connected service.

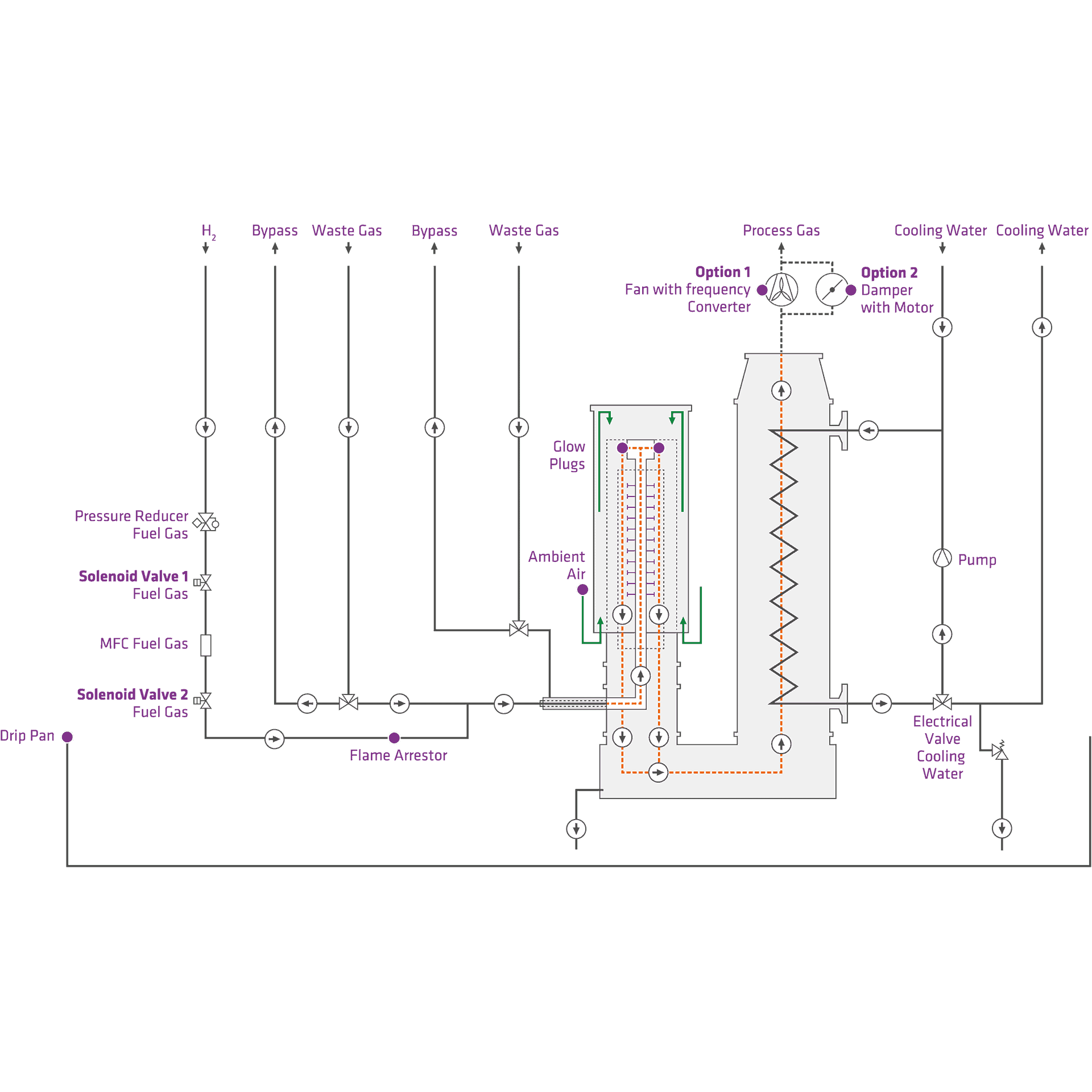

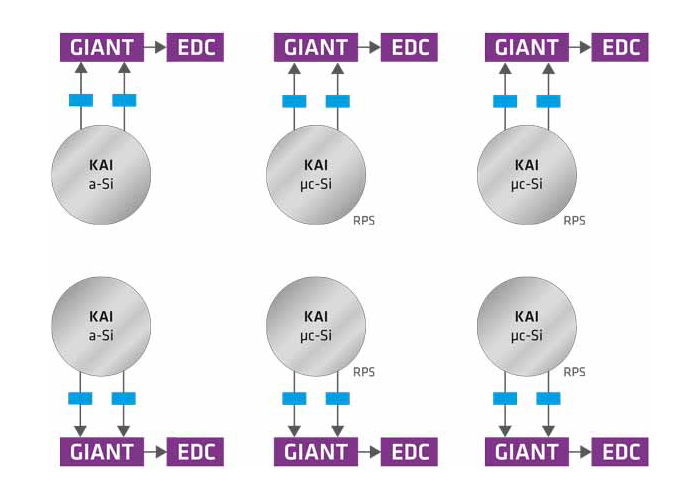

Point-of-Use Waste Gas Treatment Systems

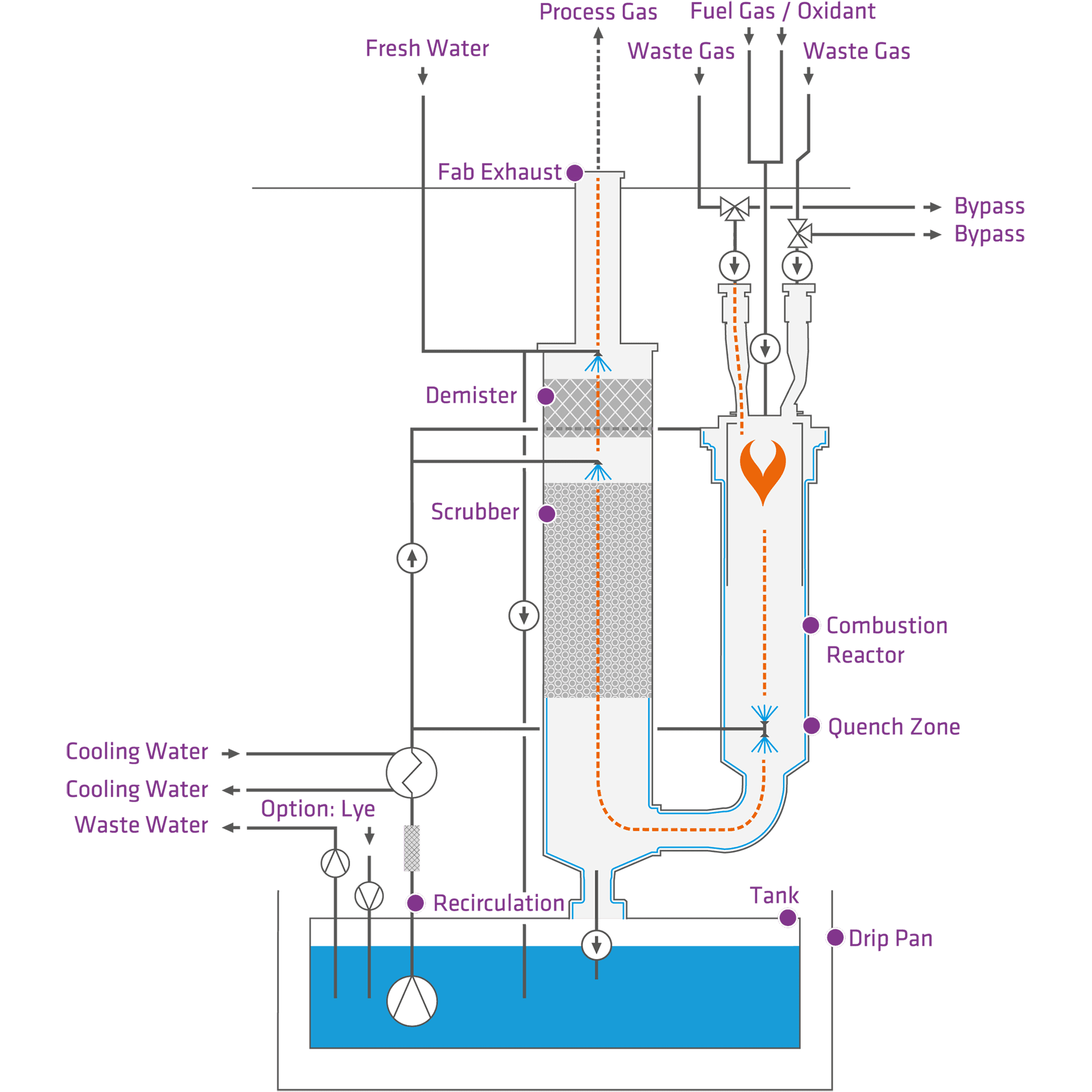

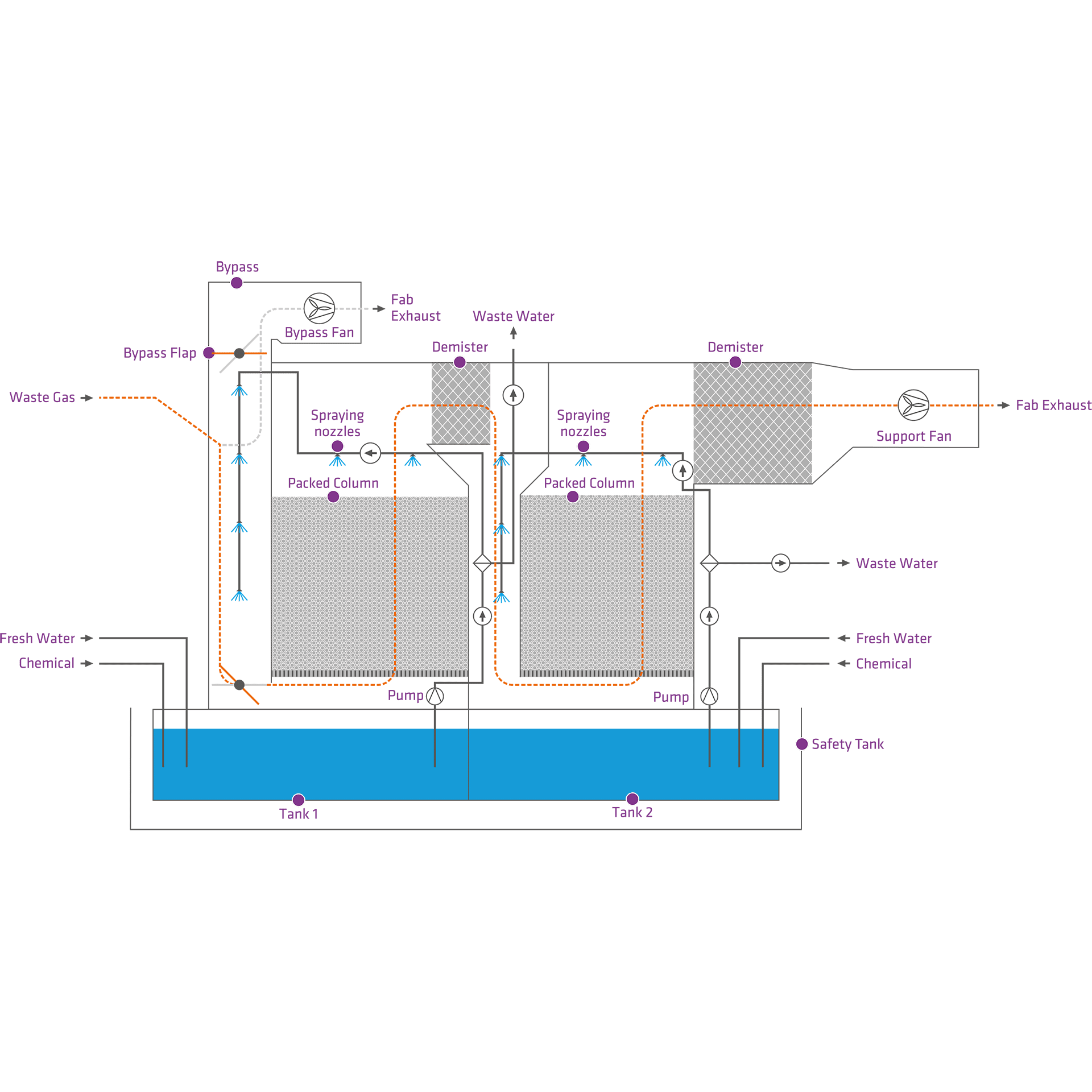

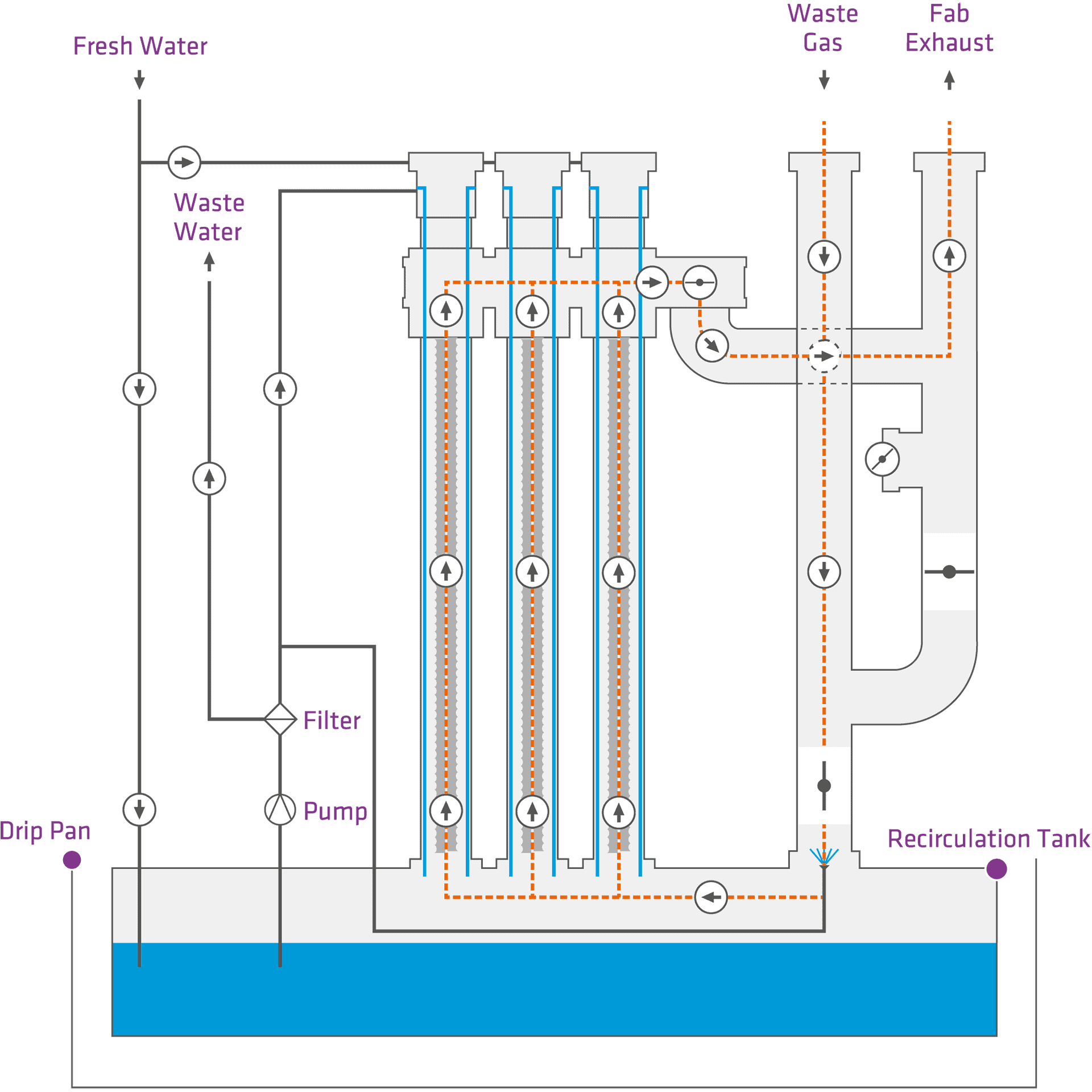

Point-of-use waste gas abatement systems of DAS Environmental Experts treat process gases as they accrue e.g. in the semiconductor, photovoltaic, LED and TFT industry. DAS scrubbers treat condensable, flammable, corrosive, reactive, toxic and/or pyrophoric gases and fine dust. Our process portfolio includes burn/wet systems, wet scrubber, pyrolysis and electrostatic filters.

Optimization of Waste Gas Abatement Systems

For the client, process optimizations very often cause changes in composition and quantity of process waste gases, thus leading to changing requirements regarding the waste gas treatment system. Changing industry standards for system components and modules also require continuous and further development in waste gas treatment systems.

Service and Maintenance for Waste Gas Treatment Systems

DAS service teams are at your disposal 24/7 on demand or as a constant onsite team at all worldwide high-tech sites. Our customer support includes start-up, professional maintenance and technical support. We work exclusively with original spare and consumable parts across the world to ensure the safety and efficiency of waste gas treatment.

Our Technology Portfolio for industrial Waste Gas Treatment

Industries and References

DAS Environmental Expert offers custom-fit and effective solutions to manufacturers of high-tech products worldwide. This is our contribution to the technological development of our society aligned with the protection of people and the environment.

Waste Gas Treatment for Environmental Protection and Safety in the Industry

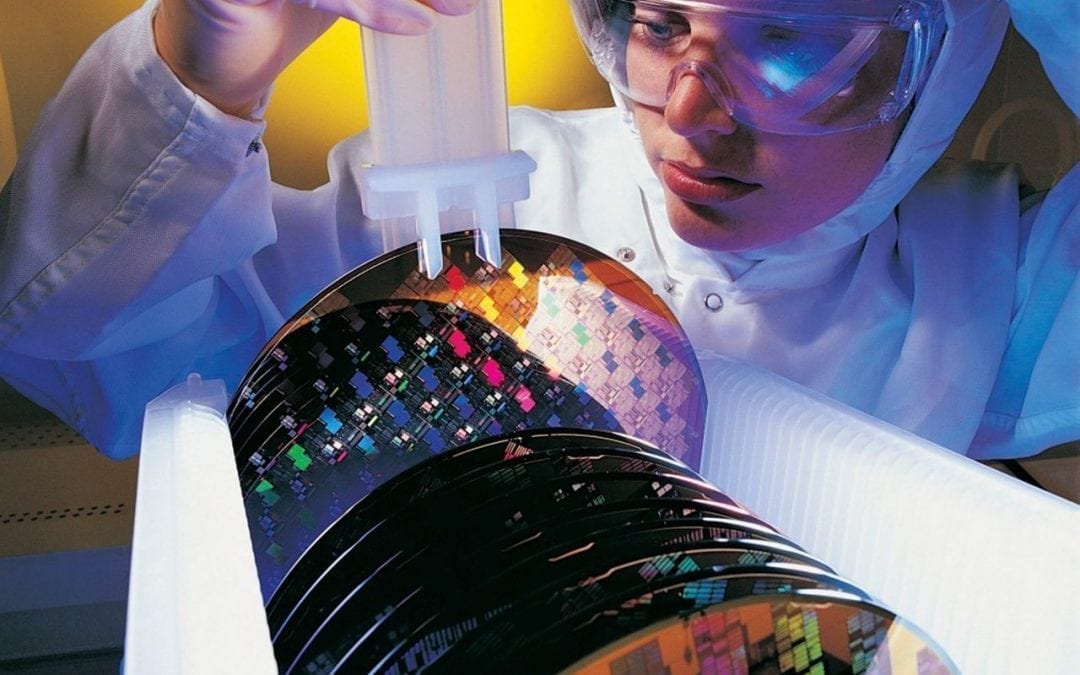

The manufacture of microchips, solar cells, flat screens, and Light Emitting Diodes (LEDs) requires highly complex, multistage manufacturing processes that produce harmful waste gases. Such process steps can be etching, CVD, epitaxy or TCO. The waste gases need to be treated immediately at the point-of-use for several reasons:

1. Health and Safety:

Many of the process gases used are flammable or explosive such as hydrogen (H2) or silane (SiH4) while others are poisons (COF2, HBr, F2) and so must be treated before coming into contact with people or wildlife.

2. Environmental Protection:

Many gases used are dangerous for the environment. Tetrafluoromethane (CF4) for example, has a lifetime of approx. 50.000 years in the atmosphere and a Global Warming Potential of 6.500 times that of carbon (CO2).

3. Stability of Manufacturing Processes:

A lot of waste gases contain a lot of particles or dust in the gas flow. This dust has the possibility to disrupt the facility exhaust leading to unintended downtime in the manufacturing plant. What makes the dust difficult to treat is that the particle size is often submicron and easily passes through wet scrubbers or physical filters without being trapped in the scrubbing liquid.

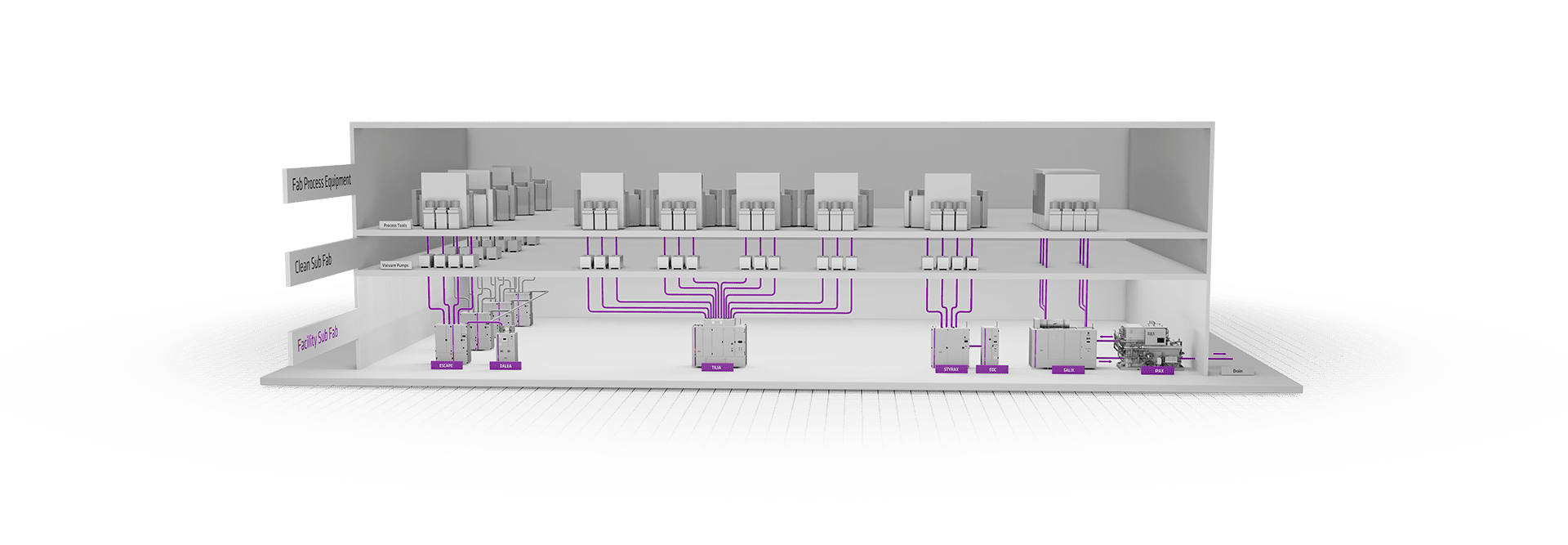

Typically gas treatment tools are situated in the sub fab and placed after the vacuum pumps. The physical closeness to the vacuum pumps results in several advantages, a shorter gas line between the two tools with less chance leaks and a cost saving potential as some processes require this line to be heated to avoid condensation within the waste gas line. The application of waste gas treatment systems furthermore reduces the demand for cleaning and maintenance at the gas lines. Our case studies section will give some examples.

Consulting and Technology Selection

The selection of the appropriate technology is carried out by our application specialists after analyzing the situation on site. Information about the process tool, vacuum pump, gas types and flows as well as the available operating materials are decisive.

In order to ensure a long-term runtime and tool availability, our service and technical support are available on demand or on-site as soon as the system is commissioned.

Dr. Christian Kuhne

Director Sales Global