DAS Environmental Expert Systems Reliably Treat Waste Gases from MEMS-Production

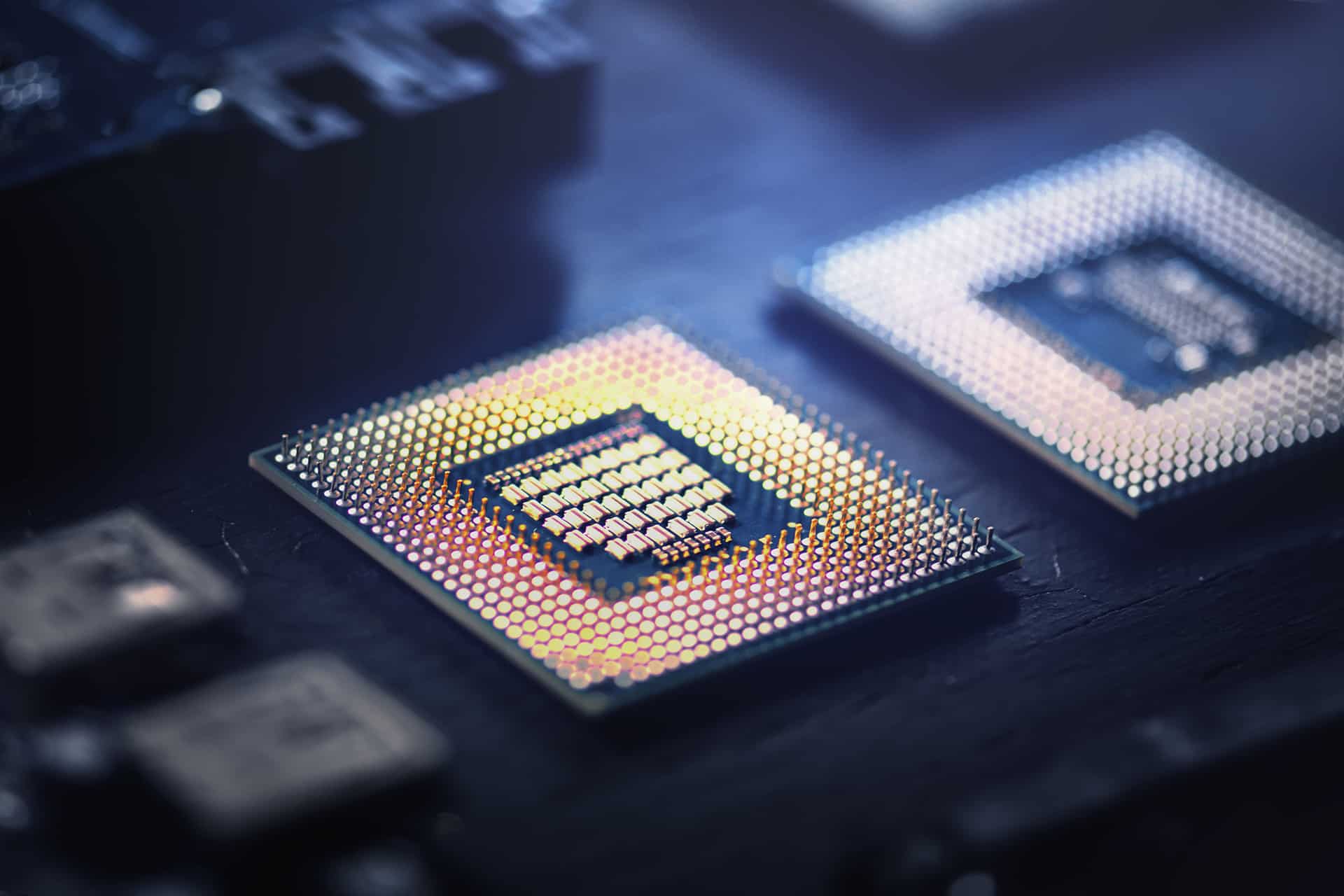

Micro Electromechanical Systems (MEMS) combine, on one chip, mechanical components such as sensors, actuators, and electronic modules such as evaluation and communications technology. MEMS that have added optical elements are called Micro-Opto-Electromechanical Systems (MOEMS). DAS Environmental Expert offers reliable waste gas treatment solutions for MEMS and MOEMS production.

Abatement Technology Made in Dresden for a Growing Market

For future-oriented technologies such as Industry 4.0, self-driving vehicles and the Internet of Things (IoT), MEMS-components are of fundamental importance because they are the link between the analog and digital world, and the switchboard of digital data processing.

In accordance with the rapid development of these future-oriented technologies, the markets and market shares of MEMS are growing. Already, MEMS are in high demand in the automotive sector where they contribute to improving driving comfort and safety.

Increasing quantities of MEMS are also produced for applications in automation technology.

During the manufacture of MEMS, DAS Environmental Expert waste gas treatment systems effectively complement the manufacturing technology. Regardless of the equipment or processes used, our abatement technology reliably removes hazardous substances directly at their point of origin (Point-of-Use) from the exhaust gas flow.

Point-of-Use-Waste Gas Abatement Systems Increase Safety for Each Step of the MEMS Manufacturing Process

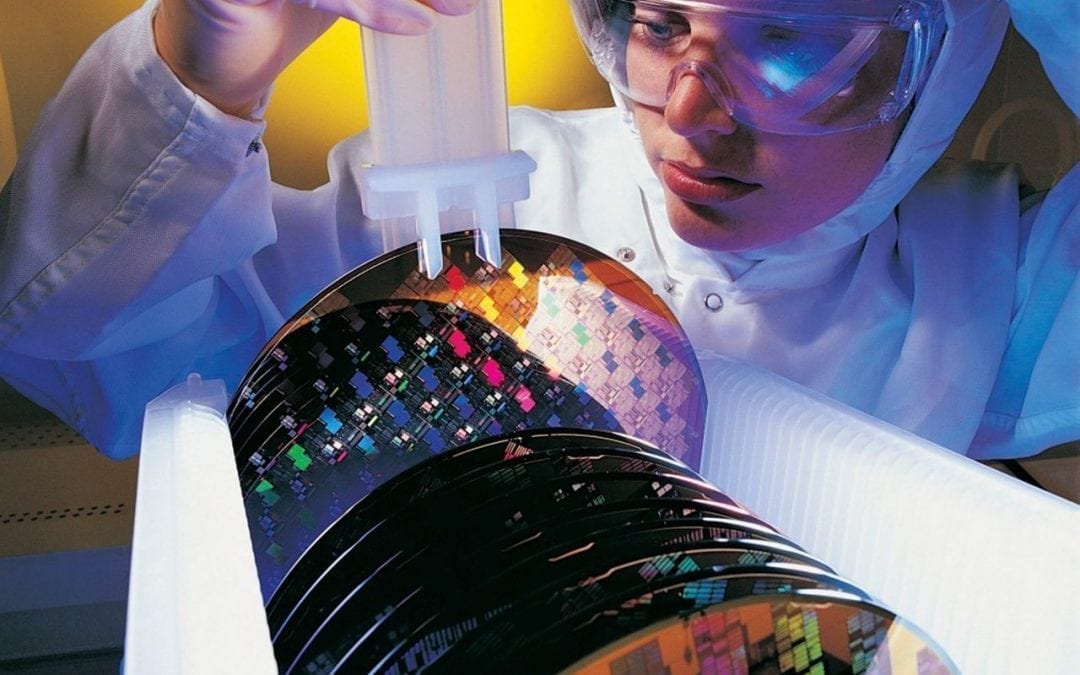

The manufacturing of MEMS utilizes processes typical to the semiconductor industry. Microsystems on one chip, for example, employ the common technologies of microelectronics plus some additional, specialized process steps. Since the 1990s, when it was founded, DAS Environmental Expert develops, manufactures and installs customer-specific waste gas abatement technology for the semiconductor industry. On customer demand, we also provide system servicing and maintenance.

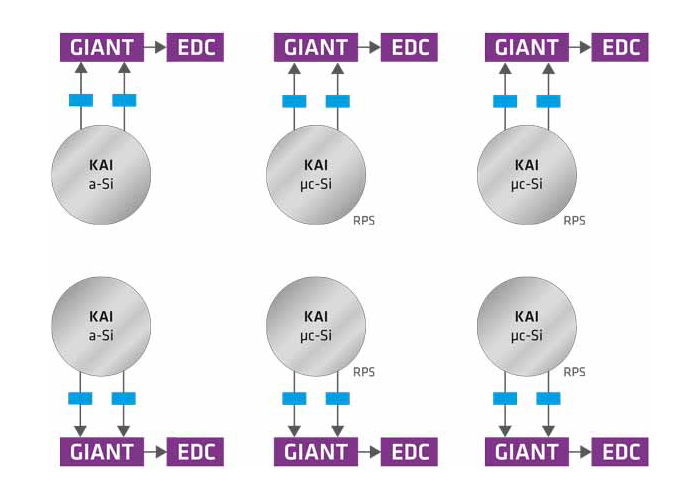

Of the varied options to deposit thin films from reactive sputtering, ALD (Atomic Layer Deposition) and (CVD/PECVD (Chemical Vapor Deposition/Plasma-Enhanced Chemical Vapor Deposition) to diverse technologies for etching and structuring and wafer cleaning, we offer the suitable waste gas treatment solution for all process steps. Our technology is a flexible, integrated system concept. Based on creating a small footprint, our system usually fits inside a cabinet and requires less than one square meter (10.8 square feet) of footprint.

Thus, the abatement of hazardous gases and gaseous mixtures happens safely and reliably directly at the Point-of-Use. Harmful substances are removed through burner/wet systems with separate burner and wet (scrubbers) and the aid of electrostatic filters. The residual gas can promptly be released into the environment through an exhaust system. The exhausts from our systems meet all regulatory requirements.

Our portfolio lists abatement technologies for all processes employed in MEMS manufacturing. Our systems operate fully automatically and are sensor-controlled. They meet the highest safety standards as documented by our numerous relevant certifications.