Zuverlässige und sichere Abgas- und Wasserbehandlung für die Solarindustrie

Bei der Herstellung von Solarzellen werden unterschiedliche Gase freigesetzt. Unsere kompakten und effizienten Abgas-Anlagen kombinieren sichere und zuverlässige Wasch- und Brennvorgänge auf engsten Raum. Mit dem Bewusstsein, dass die Abgasreinigung maßgeblich für die Sicherheit des Fertigungsprozesses ist, entwickeln und fertigen wir Brenner/Wäscher-Entsorgungslösungen und Elektrostatische Filter für Abgasströme bis 5.000 m³/h.

Unsere Kunden in der Solarindustrie profitieren von unserem ausgeprägten technischen Verständnis für die Produktionsprozesse für Dünnschicht-Silizium-Module und kristalline Zellen, insbesondere für CVD‑, TCO- und Trocknungsprozesse.

Prinzipiell können DAS-Anlagen kondensierbare, brennbare, korrosive, reaktive, toxische und/oder pyrophore Abgase (z. B. Silane, Silanorganika, Terpineole, Wasserstoff, Ammoniak oder Halogenwasserstoffe) sowie Feinstäube behandeln.

Experten von DAS Environmental Expert stehen dabei nicht nur für die Planung der Erstaustattung zur Verfügung, sondern helfen auch bei der Optimierung und Kostenreduzierung im laufenden Prozess. Erfahren Sie mehr durch unsere Fallstudie zur Kostenreduzierung bei einer Silizium-Dünnschicht-Produktionslinie.

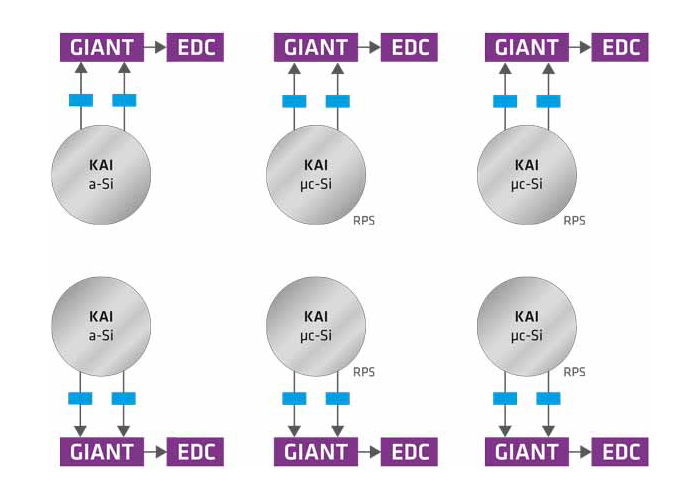

Point-Of-Use Abgas- & Abwasserreinigung von DAS EE für die Solarindustrie

Einblick in unser Produktportfolio:

- Abgasreinigungsanlagen

- Entfernung kondensierbarer organischer Verbindungen (VOC´s)

- Reduktion von Feinstaubemissionen

- (Ab-)Wasserbehandlung und Recycling

Pollution Abatement Facility: Die kombinierte Abgasreinigung und Abwasserbehandlung für die Solarindustrie

Säubern und Spülen, Schneiden und Sägen, Beizen, Texturieren und Beschichten bis hin zur Reinigung der Fab – in der Solarindustrie entstehen entlang der Prozesskette rund um die Verarbeitung von Silizium unterschiedliche stark belastete Abgase und Abwässer. Es fallen Feinstäube, aber auch stark alkalische oder saure Wässer an, die behandelt werden müssen. Auch die Entfernung von PEG, Fluorid oder Ammonium aus dem Wasser kann je nach Prozess notwendig sein. Zudem wird Reinstwasser mit hohen Anforderungen in der Produktion benötigt.

Mit dem Pollution Abatement Facility for Solar Fabs (PAF) bitet DAS EE eine ganzheitliche Anlage aus einer Hand, die speziell auf die kombinierte Abgas- und Abwasserbehandlung von Produktionsstätten der Solarindustrie angepasst ist.

Ihre Vorteile

- Integrierte Abgasentsorgung plus Wasser- und Abwasserbehandlung

- Sicher, zuverlässig, kosteneffizient

- Global bewährte Referenzen

- Kosteneinsparung dank Wasserrecycling

- Entfernung von Feinstaub und Aerosolen

- Skalierbar von Laboranwendungen bis zur Gigawatt Fabrik

- Effizienter Chemikalieneinsatz dank abgestimmter Systeme

Anwendungsbereiche

- Abwasserbehandlung nach Abgasreinigung

- DI-Wasser-Aufbereitung

- Behandlung von Wasch- und Spülwässern