TSUGA – Bay Solution with Multifunctionality

TSUGA is the stand-alone bay solution for post combustion waste gas treatment for NOx and particulate matter in the semiconductor industry.

Waste Gas Treatment – TSUGA

Post Combustion Waste Gas Treatment for NOx and Particulate Matter with TSUGA

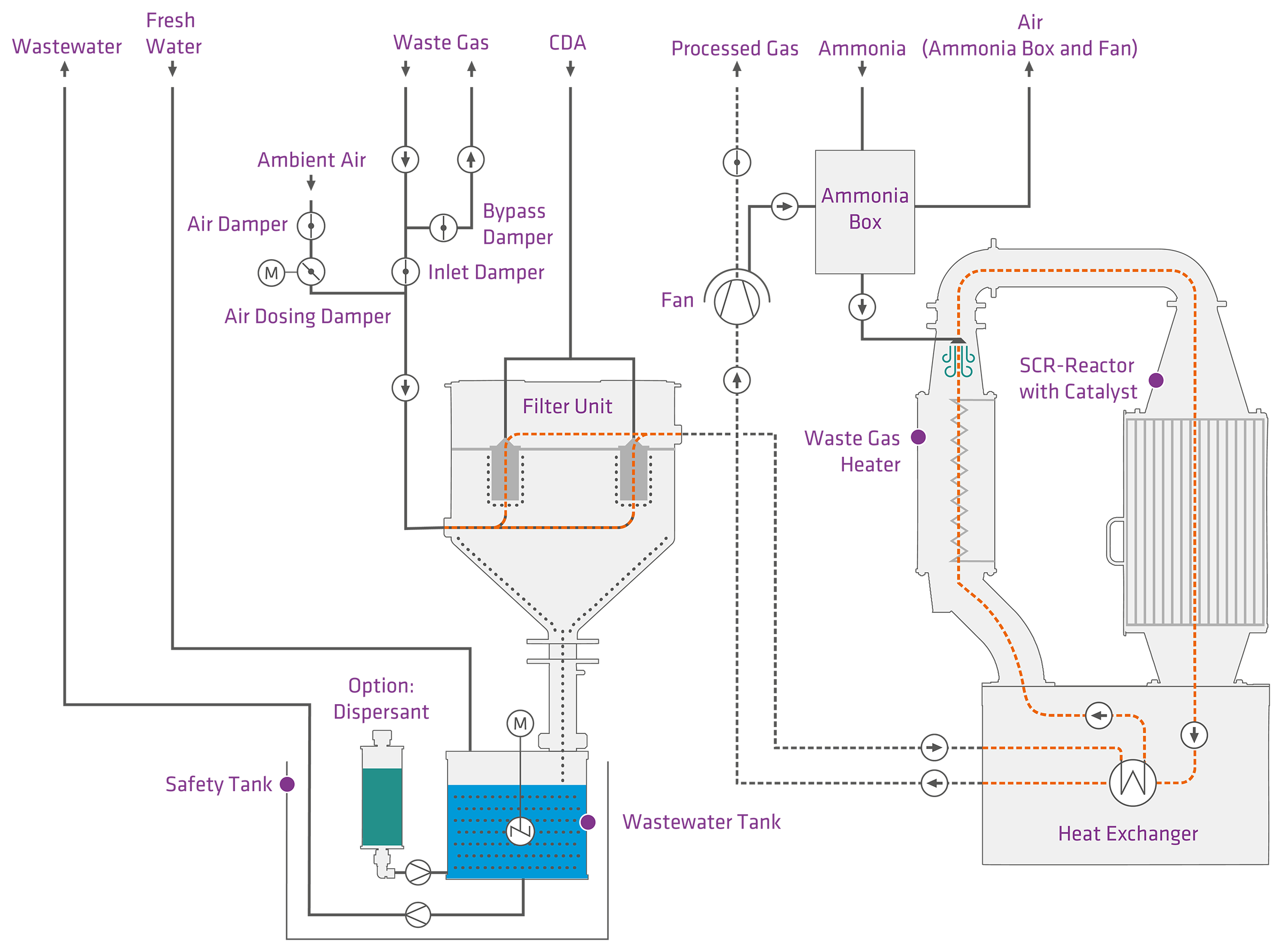

Functioning principle of the Selective Catalytic Reduction and Membrane Filter

DeNOx: SCR (Selective Catalytic Reduction) with Ammonia

- High reduction efficiency regardless NOx source: up to 95% *

- Low NH3 slip: 10 ppm by precise control of the dosed reducing agent *

- Flexible solution for NO and NO2 in broad concentration ranges up to 4000 ppm at total volume flow of up to 5000 slm

- Low energy demand: low temperature process and energy recovery by heat exchanger

DeDust: Membrane Filter (Surface Filtration)

- Necessary pre-treatment for catalyst

- High reduction efficiency of PM2.5, PM10, total dust fraction (up to 99.9%)

- Applicable for typical post-combustion PM pollutants

* Tradeoff between NOx DRE and NH3 slip: Increase of DRE will result in increase of slip and vice versa.

TSUGA — Stand-Alone Bay Solution

Application

- Secondary abatement after NOx generating abatement systems, e. g. Burn-Wet Systems

Goals

- High NOx reduction efficiency and low NH3 slip to facilities

- High dust removal efficiency

- High capacity

- High underpressure stability

- Secondary abatement after NOx generating abatement systems, e. g. Burn-Wet Systems

- No impact to upstream abatement systems

- High energy efficiency

Technical Data

| TSUGA | |

|---|---|

| Dimensions (W x D x H): | 1980 mm x 1200 mm x 1940 mm |

| Maintenance area: | Front side |

| SCR-Reactor with Catalyst: | High volume flow capacity up to 5000 slm |

| Particle Filter: | PM2.5, PM10, total dust fraction: up to 99.9% |

Consulting and Technology Selection

The selection of the appropriate technology is carried out by our application specialists after analyzing the situation on site. Information about the process tool, vacuum pump, gas types and flows as well as the available operating materials are decisive.

In order to ensure a long-term runtime and tool availability, our service and technical support are available on demand or on-site as soon as the system is commissioned.

Dr. Christian Kuhne

Director Sales Global