Efficient Waste Gas Treatment for LED Industry

Safe LED Manufacturing with DAS Abatements

In LED manufacturing, large amounts of ammonia and hydrogen are used as process gases. Recognizing this trend, the environmental engineers at DAS EE have developed innovative and eco-friendly solutions for gas treatment. The LED industry is one of the fastest-growing high-tech markets, expanding from display backlighting to general lighting. With this growth come higher emissions, requiring effective waste gas treatment. DAS EE meets this need with advanced systems like LARCH for MOCVD processes.

Efficient Treatment of Hydrogen and Ammonia

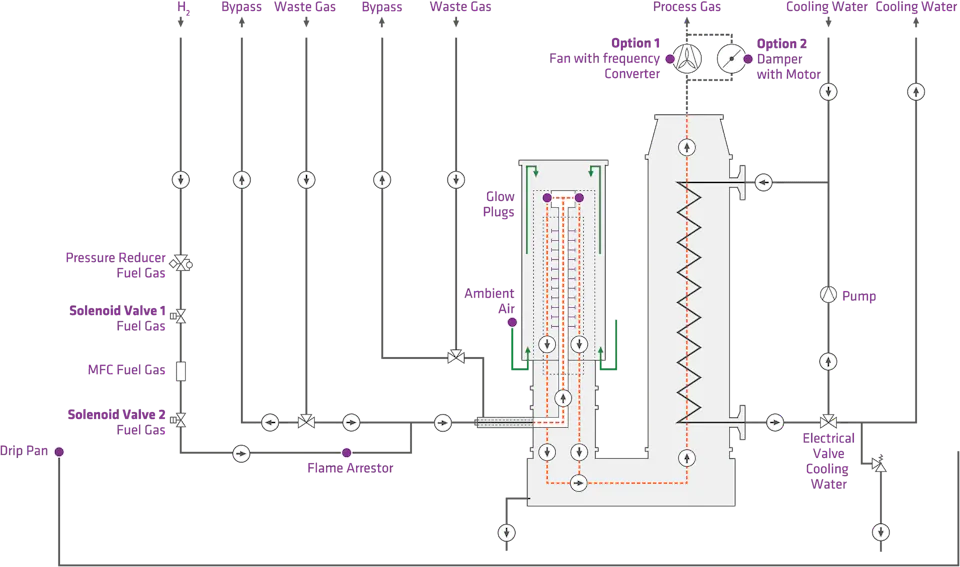

The environmental experts at DAS EE developed LARCH, a waste gas treatment system designed for MOCVD processes. It handles large flows of hydrogen and ammonia, as well as smaller amounts of metal-organics and dopants typical in LED production.

The system works in three stages: first, ammonia decomposes in a special decomposition zone; next, hydrogen is ignited and oxidized; finally, gases are cooled via a heat exchanger.

Thanks to DAS technology, the cleaned gas can be safely released into the environment. Sensors and redundant safety systems ensure stable operation. LARCH achieves low emission levels and replaces traditional wet scrubbing, offering a more eco-friendly and efficient solution.

Your Contact Person for all Questions on Waste Gas Treatment

For customized abatements for safe waste gas treatment in LED industry.