Waste Gas Treatment with Rotary Dust Collector

The systems of the RDC range use centrifugal force to separate fine dust particles. They are based on the purely mechanical rotor-stator principle.

DALEA – Rotary Dust Collectors at Point-of-Use

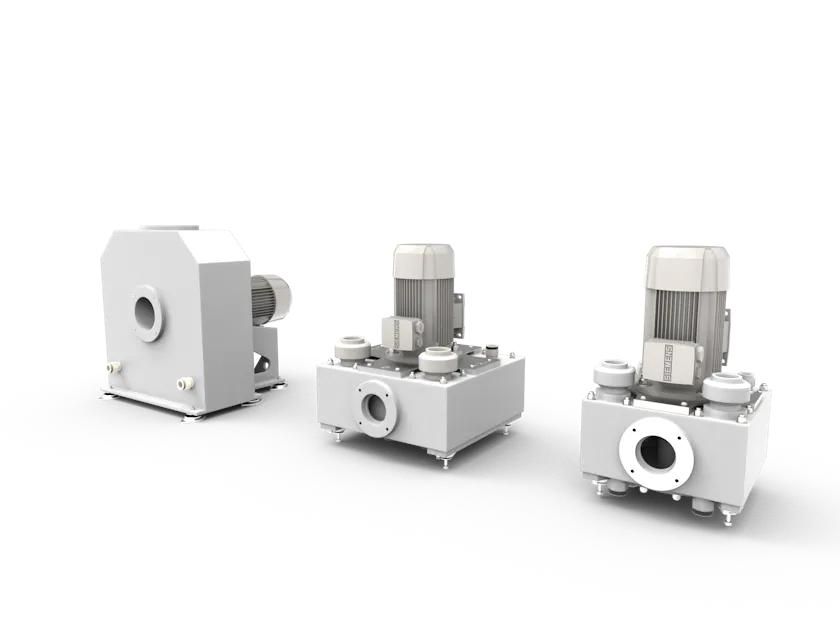

Rotary Dust Collectors – Our Portfolio

A jet of water is atomized by a high-speed rotating disc. The result is a mist of very fine water drops in which dust particles are centrifuged. The rotor ensures that the waste gases are aspirated and thus moved forward without loss of pressure. The turbulence in the shear gap between the rotor and stator ensures that the water mist and particle-laden process gases are mixed together effectively. The fine dust particles are suspended in the water; the purified waste gas can then be released freely into the environment.

RDC – can be integrated into or added to classic burn/wet systems

The RDC range was developed by DAS Environmental Expert GmbH in response to a client’s request. The systems are small, which means they can be integrated into or added to the classic burner-scrubber systems. RDC systems can also be used for much higher dust loads than the EDC systems, as well as for higher waste air flows. In addition, the rotor works as a blower and moves the waste gas forward; this prevents any loss of pressure and even supports the extraction that normally follows. However, RDC systems do not have the same degree of separation efficiency as the EDC range.