Wastewater Treatment for the Cosmetics Industry

The cosmetics industry accrues many kinds of wastewater. The challenge for wastewater treatment is that product lots are often changing, thus changing the composition of the wastewater. Switching to a new product lot, produces large amounts of wastewater that are contaminated by surfactants, dye, oils and emulsions and high COD concentrations. In addition, wastewaters foam excessively at times.

DAS Solutions for Wastewater Treatment in the Cosmetics Industry

The specific loads from surfactants, dye, oils and emulsions differ significantly between product classes and lots. Therefore, our customized systems are flexible and can be expanded at any time. If required, they adopt to differing foam quantities in a short time.

DAS Environmental Expert plans and manufactures integrated processes for biological wastewater treatment. After a detailed analysis of the specific wastewater composition our experts identify a customized concept assuring a targeted, efficient and cost sensitive treatment of your wastewater.

Effective Processes for Cost Efficient Water Recirculation

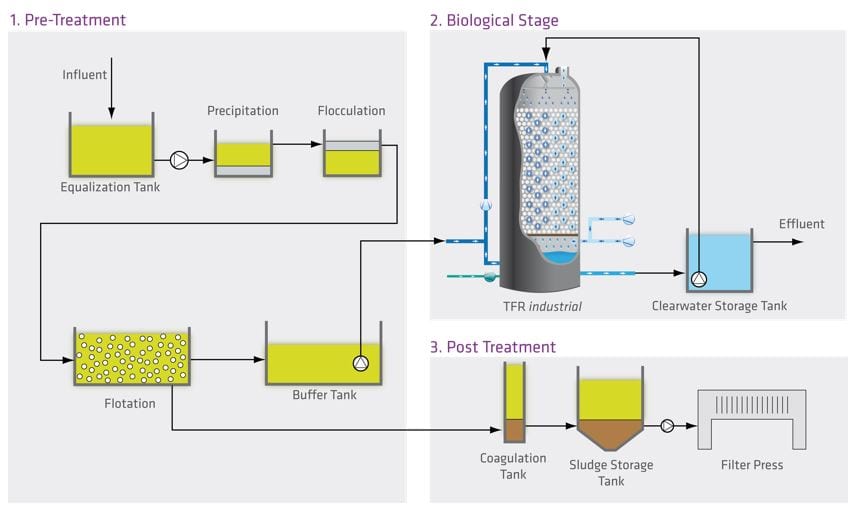

In addition to developing problem-specific wastewater concepts, DAS Environmental Expert plans and manufactures integrated processes for biological wastewater treatment. The high adaptability of our wastewater technology and systems paired with the high adaptability of the biomass enables to degrade persistent substances and surfactants at little energy input. Highly loaded stream branches are treated separately. Mechanical separation processes, such as flocculation, filtration and floatation remove first pollutants while customer-specific methods discolor the wastewater.

Treating the wastewater with DAS technology reduces cost by recycling the water, which reduces the amount of wastewater, thus saving sewage charges.

Cosmetics Manufacturer Emil Kiessling GmbH Applies Smart Wastewater Treatment– with the Disposal Technology from DAS

Emil Kiessling GmbH with headquarters in Georgensgmünd, Middle Franconia (Germany), is a successful cosmetics manufacturer. The product range includes natural cosmetics through to sun protection. Regarding its wastewater treatment, the company relies on the technology portfolio of DAS: Since 2011 a combined chemical-physical and biological wastewater treatment allows an efficient reduction of the Chemical Oxygen Demand (COD) in the wastewater. This relieves the sewer system and the municipal treatment plant. The installed systems´ capacities can be compared to a population equivalent of 5.000 people. Due to the effectiveness of the TFR technology the plant consumes 45% less energy than similar plants.

Your contact person for all questions on wastewater treatment