Planning and Design of Waste Gas Treatment Systems

Waste Gas Treatment Solutions for Different Challenges

Choosing the right waste gas treatment system requires an analysis of the individual circumstances. Equipping a new factory may bring up other results than optimizing and extending existing installations.

Space availability for equipment and service, the provision of fuel gases and the costs of water and electricity play an essential role for the selection of the suitable waste gas treatment. While innovative developments can be taken into account right from the start in the construction of new factories, fab expansion can be much more challenging for the subfab.

We support the manufacturers of high-tech products, building designers and OEMs in the ideal planning of abatement solutions. For this purpose, we develop customer-specific abatement concepts that go beyond pure waste gas purification.

Planning Support for Manufacturers, Building Designers and OEMs

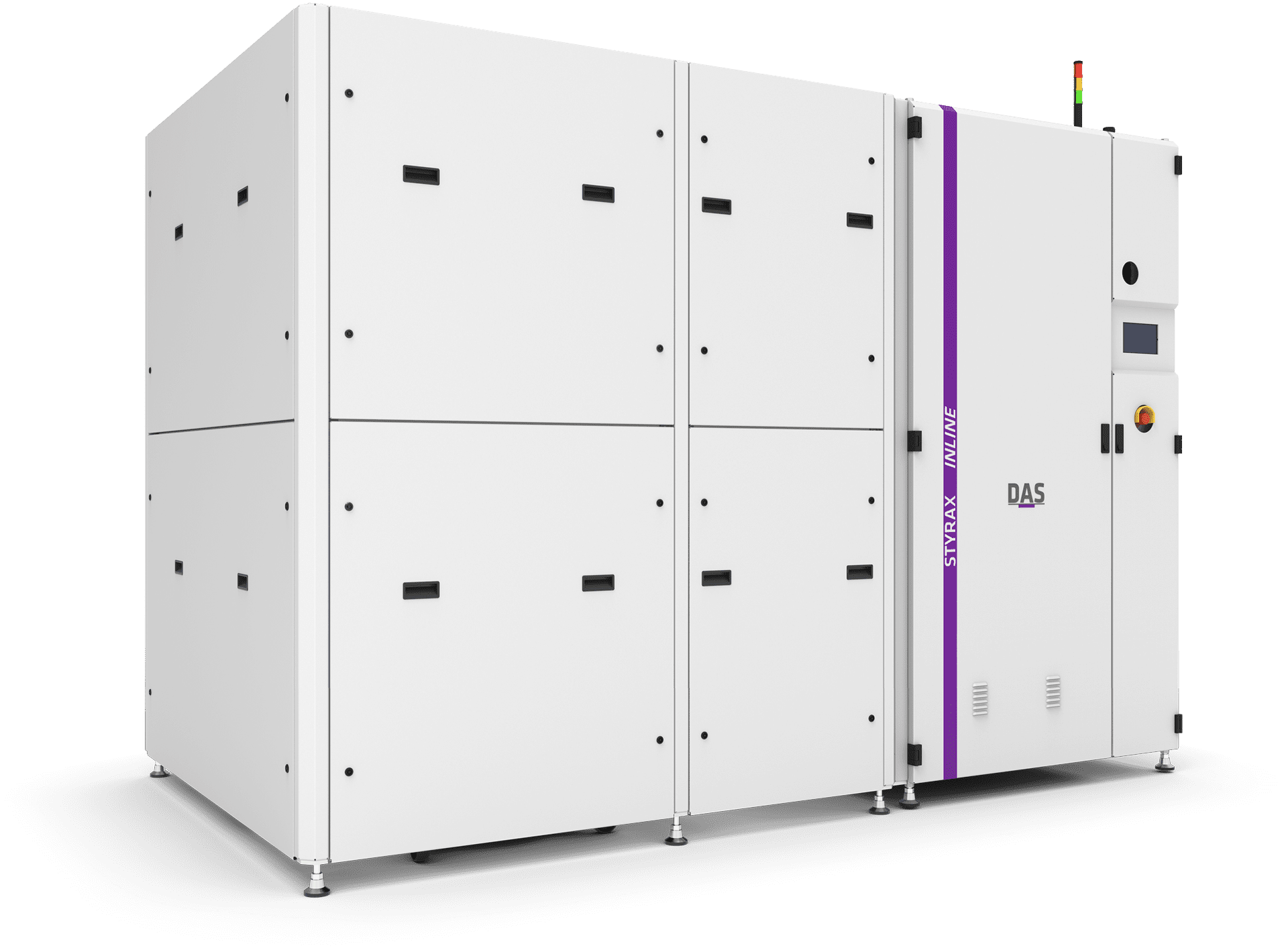

DAS Environmental Experts partners with manufacturers, building designers and OEMs to develop and deliver the best possible treatment concept for process waste gases in the high-tech industry. Early consideration of the planned subfab capacities, media supply and process coupling enables potential savings in planning expenditures, space requirements as well as media connections and consumptions.

Enhanced Solutions for Waste Gas Treatment

The basic requirements for waste gas treatment are the same in all high-tech industries worldwide: harmful waste gases need to be treated directly at the point of use in order to protect people and the environment. Besides that, the sustainable design of waste gas treatment systems goes along with expanded safety parameters, cost and energy saving potentials, and cutting-edge service.