Efficient Solution for Reducing Nitrogen Oxide (NOx) Emissions in the Semiconductor Industry

Acid rain and heavy smog — these threats to health and nature are caused by NOx (nitrogen oxides NO2 and NO). Dealing with harmful NOx produced during combustion processes is a real challenge in many industries.

DAS Environmental Experts has developed a turnkey solution for NOx treatment that is suitable for the semiconductor industry and other industries.

What are Nitrogen Oxides and what Effects do they have on the Environment and Health?

Nitrogen oxides, abbreviated to NOx, are gaseous compounds produced by the combustion of fossil fuels such as oil, gas, coal or wood. The group of nitrogen oxides includes nitrogen monoxide (NO) and nitrogen dioxide (NO2).

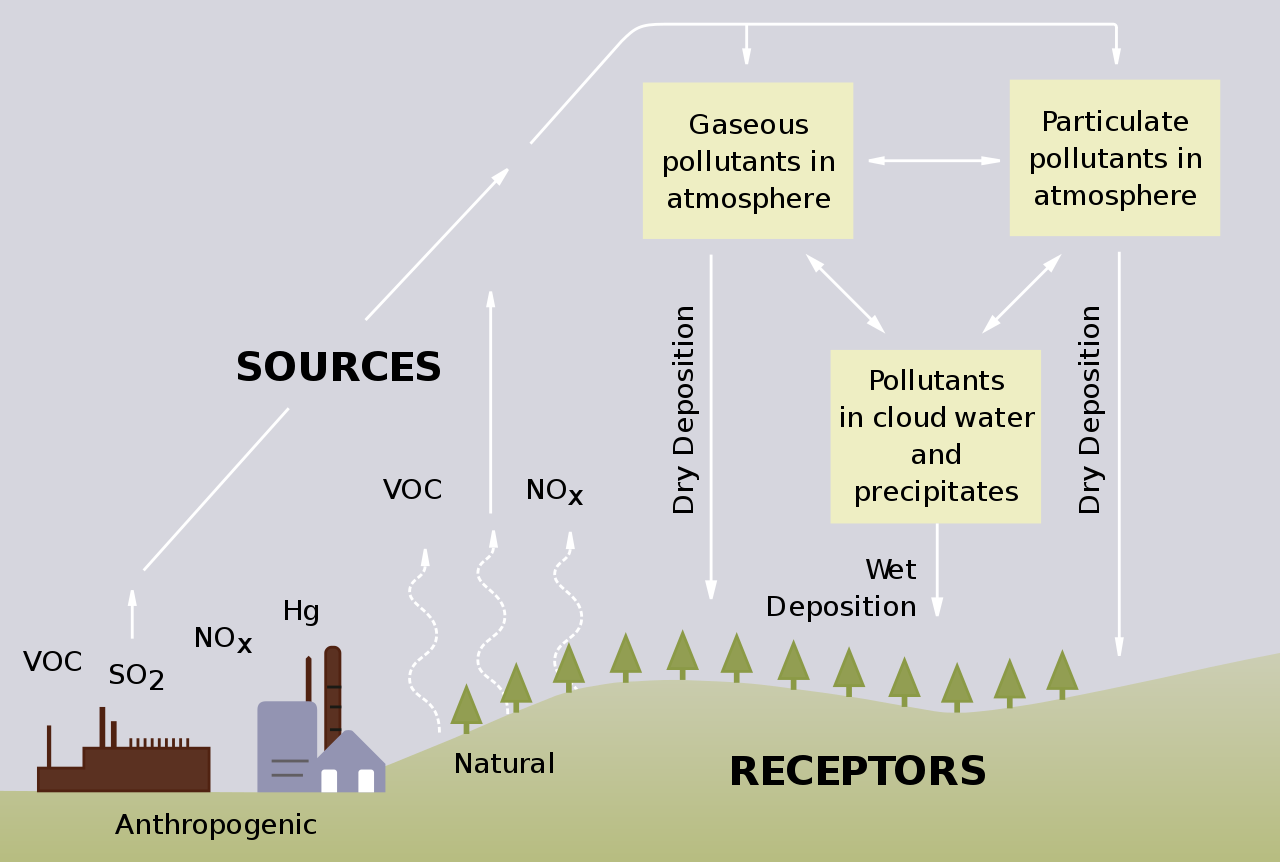

Nitric oxide (NO) is a colorless, bioactive substance that is used in the body as a messenger substance, among other things. It has a dilating effect on blood vessels and is therefore used in cardiology and heart surgery as well as for the treatment of pulmonary hypertension in newborns. NO can be easily oxidized to NO2 in the atmosphere. Nitrogen dioxide (NO2) is a reddish-brown, highly toxic, pungent-smelling gas that decomposes into nitrogen monoxide and oxygen at temperatures above 200 °C. It forms acid with water and leads to the formation of acid rain; both nitrogen oxides also contribute to the formation of summer smog. The health of humans and animals is endangered by these substances, as nitrogen oxides — especially nitrogen dioxide — irritate and damage the mucous membranes of the respiratory tract and eyes and impair lung function. Inhaling these nitrous gases in high concentrations is extremely dangerous; among other things, it can cause respiratory distress and pulmonary oedema.

A not insignificant proportion of air pollution is caused by traffic (approx. 37% of total emissions). The stationary sources of pollution, which account for around 30% of emissions, are mainly power stations, waste incineration plants, glass and cement production and oil refineries. Nitrogen oxides can be released not only during combustion processes, but also when working with nitric acid. In addition, the relevance of agriculture as a source of NOx emissions is increasing (approx. 10%).

For this reason, strict limits already apply to nitrogen oxides in many countries around the world. Governments and authorities around the world are endeavoring to further restrict the release of these air pollutants. National environmental regulations such as the TA-Luft in Germany or the EPA in the USA set strict limits for NOx emissions. This is why not only the large NOx emitters mentioned above, but also high-tech industries such as the semiconductor industry, require effective solutions to prevent, reduce or treat nitrogen oxides.

Source: https://www.epa.gov/

How are nitrogen oxides generated?

NOx is mainly formed by the oxidation of nitrogen during various combustion processes. A distinction is made between three formation mechanisms. Thermal NOx is formed at relatively high temperatures (over 1300°C) from the nitrogen and oxygen in the combustion air. Fuel NOx is formed from nitrogen chemically bound in the fuel at temperatures of 800°C and above. These complex chemical processes can be strongly influenced by the reaction conditions. It is also possible for nitrogen to be converted to nitrogen oxide, known as prompt NOx, under the influence of fuel radicals (CHx) in the flame front.

In normal combustion processes, 95% of NOx consists of NO. NO2 is mainly formed after combustion with the oxygen in the atmosphere. However, unfavorable process control can also lead to the formation of nitrous oxide (N2O), better known as laughing gas. This substance is used, for example, in medicine as an anesthetic and in the food industry as a propellant. Above all, nitrous oxide is considered a greenhouse gas with an impact 298 times greater than CO2.

Contact

Your contact for all questions about our efficient solution for reducing nitrogen oxide (NOx) emissions.

Dr. Christian Kuhne

Director Sales Global