Customized Concepts and Solutions for Waste Gas Treatment

Enhanced Solutions for Waste Gas Treatment

Products for waste gas treatment must meet fundamental laws and standards that protect human life and the environment. Innovative DAS Environmental Expert solutions constantly strive to open up new potentials for increased product value by enhancing and advancing treatment equipment, methods and processes. There are many possibilities for enhancing the individual abatement concept.

Depending on local circumstances such as footprint limitations, specific material requirements, and the client’s philosophy regarding high-tech products, the demands on environmental technology vary. DAS Environmental Expert solutions, first and foremost, address expanded safety parameters, cost and energy saving potentials, and cutting-edge service.

IPAS – Integrated Pump and Abatement Solutions

With the IPAS-concept (Integrated Pump and Abatement Solution), DAS Environmental Experts expands its portfolio in waste gas treatment with an integrated solution that puts waste gas treatment and pumps in one cabinet. This concept can be realized with all DAS waste gas treatment plants. Clients can choose pump suppliers and integrate optional absorber cartridges and abatement solutions for fine dusts.

Short connections between pump and waste gas treatment plants lower the risk of leakage and blockage. Compared to utilizing two separate systems, this combined solution requires less space and operates with a common interface.

Solutions for Increased Safety Requirements

DAS-systems treat flammable, corrosive, toxic and reactive waste gases, along with other similar substances. Therefore, safety during the abatement process is a high priority. Sophisticated sensor technology inside DAS-systems allows for the monitoring of the system’s status at all times. Moreover, we provide our customers with diverse individual options, including:

- SEMI S2-Certification: The SEMI S2 safety guidelines define environmental, health and safety provisions for semiconductor manufacturing equipment. DAS waste gas treatment systems comply with these guidelines, and optionally, each system can be certified before delivery.

- Back-up Function: In Case of maintenance, our DUO-systems are designed to re-direct gas flow to a second burner within the system

- IPAS-Concept: Integrating waste gas treatment and pumps in a single system shortens the connections between system components and lowers the risk of leakage and blockage.

- Protection of Double Systems: Multi-chamber process facilities pose new challenges to the capacity of waste gas treatment plants. Our response is the double system TILIA. On customer demand, we have installed a stainless steel wall that separates the two systems spatially.

- Increase in Functional Safety: In the scope of new product development and product advancement, DAS introduces Safety SPS, successive control mechanisms with integrated failure safety technology that increase plant safety and simplify and accelerate troubleshooting.

Increasing Process Stability

High-tech manufacturing is at its most efficient when all processes run smoothly and the ideal throughput is achieved. Since Point-of-Use waste gas treatment plants are directly connected with the process facility, the abatement system’s running time has a direct influence on production.

Our back-up solutions ensure operations run smoothly by re-directing gas flow inside the plant to a second burner, should one burner need scheduled maintenance. This back-up technology guarantees a 99.9% availability of DAS waste gas treatment plants.

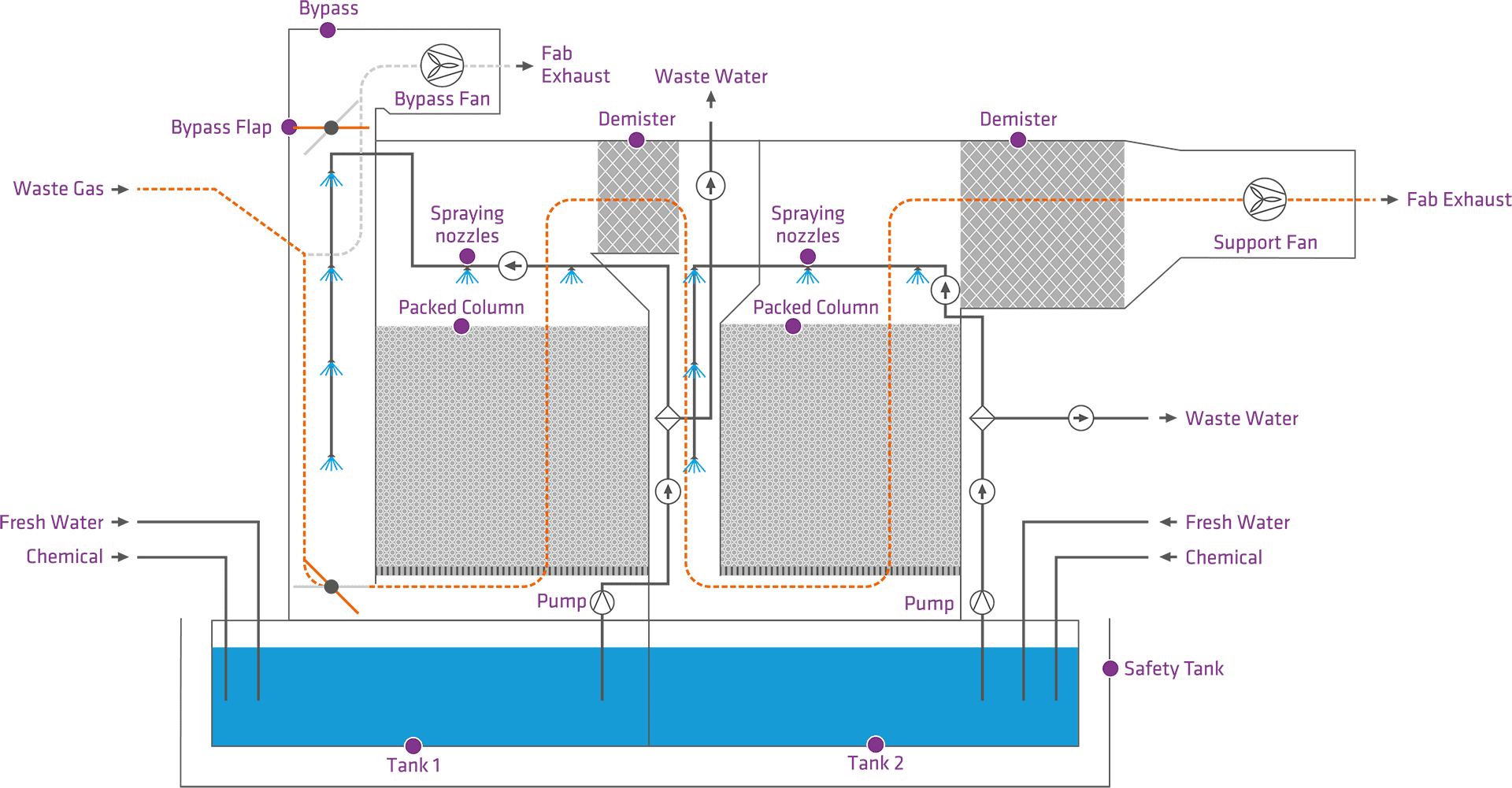

Along with this solution, our latest state-of-the-art technological developments address the topic of process stability. Our gas scrubber SALIX is designed to abate waste gases from single wafer wet cleaning. Up until now, these waste gases were directed into respective waste gas abatement systems via switching boxes, which lowered flexibility during process changes. In SALIX, all process chambers of a single process tool lead directly into the scrubber, which is connected to just one central exhaust duct.

Potentials for Energy Conservation

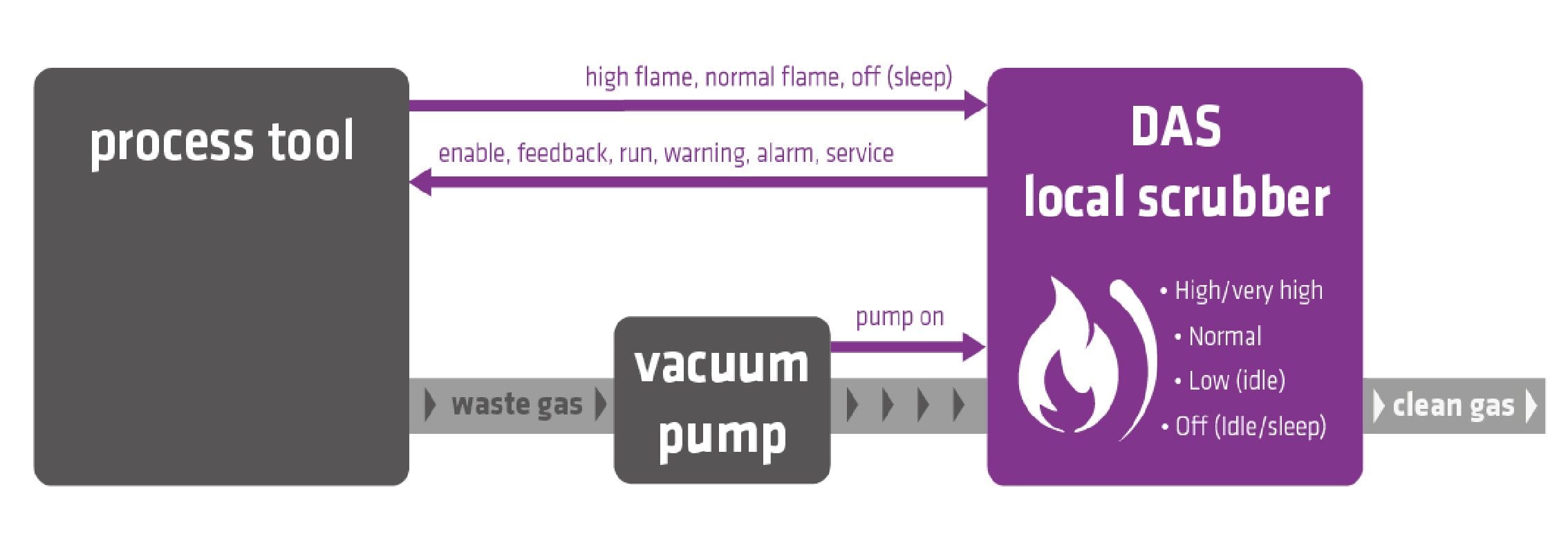

The largest potential for energy conservation in waste gas treatment plants lies in directly linking the waste gas treatment system to the process tool. Connecting both via potential-free contacts, or ethernet, for instance, the treatment plant can run at different burner capacities or switch to an idle mode. Realizing this concept can result in energy conservation in excess of 20%. More importantly, this method optimizes the consumption of fuel gas (i.e. natural gas) and oxidants (compressed air, compressed dry air ((CDA)), oxygen, water, cooling water and lye).

Connected Service

Proactive data analysis is gaining in importance in order to detect system problems and provide solutions, ideally, before a system failure occurs. DAS Environmental Experts are developing diverse solutions for proactive data analysis.