DAS EE pilot plant in the “Med-zeroSolvent” project treats solvent-containing process wastewater

Medical wastewater is a major challenge for water management — both in the clinical environment and in the production of pharmaceuticals and medical devices. The research project “Med-zeroSolvent” explores the treatment of heavily polluted process waters from membrane production.

The environmental technology experts at DAS Environmental Expert GmbH bring their many years of process and technology know-how to the project — for sustainable wastewater-reduced or even wastewater-free production.

YouTube is a service of YouTube LLC, a subsidiary of Google Inc, USA. You can find more information on data processing through this in our privacy policy. If you would like to watch this video, you also consent — revocable at any time — to the transfer of your data to the USA and the associated data processing in accordance with Art. 49 (1) a) DSGVO.

Reliable Treatment of the Solvent-containing Process Water

Dialysers for renal replacement therapy contain hollow fibre membranes, which are mainly made of synthetic polymers. During the production process, nitrogen-containing solvents such as dimethylacetamide (DMAc) are used. Waste water containing solvents is produced, some of which has to be disposed of thermally, consuming a great deal of energy and generating CO2 emissions. The partners in the “Med-zeroSolvent” research project, which is funded by the Federal Ministry of Education and Research, are tackling this challenge. Together they are working on the development of an energy-optimised, multi-stage process for the treatment of solvent-containing process water from dialysis membrane production, which makes it possible to recycle treated waste water back into production.

Pilot Plant successfully in Operation

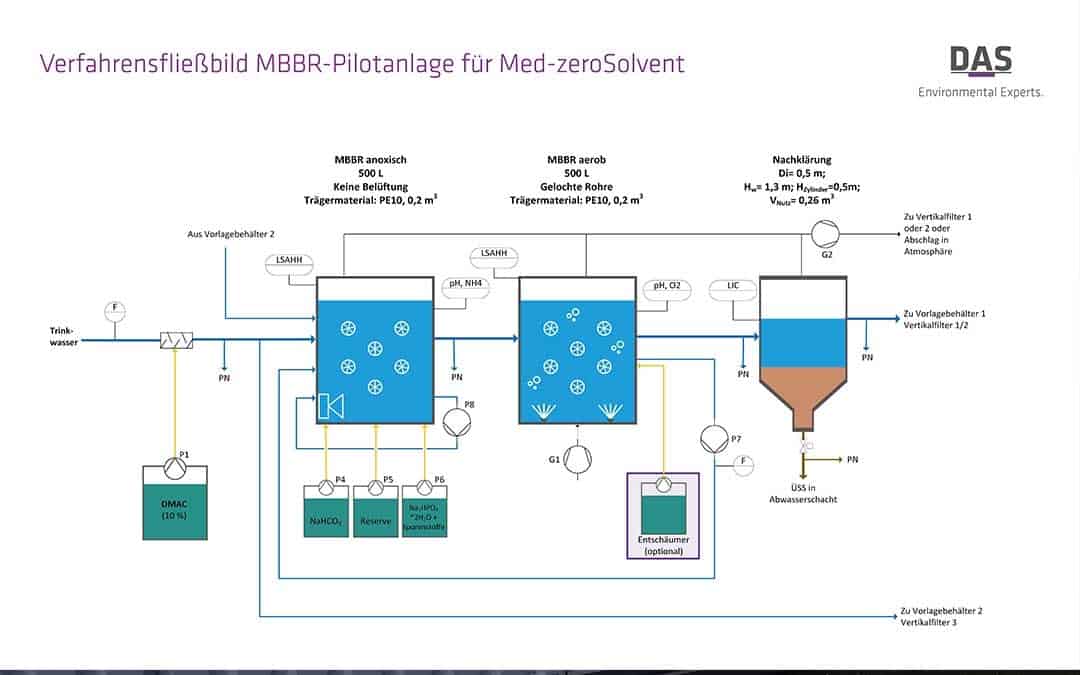

In a six-month planning phase, the DAS EE team designed and implemented the pilot plant. The commissioning will take place together with the cooperation partners in spring 2023. This milestone is preceded by an intensive preparation phase: DAS EE has been a partner of the research project, which started in April 2021, since July 2021 and is working there together with the experts from B. Braun Avitum Saxonia GmbH, the plant planners from Me-Sep and wasserWerkstatt Ingenieurbüro für ökologische Wasserwirtschaft, the analytical experts from CUP Laboratorien Dr. Freitag GmbH, the Institut für Luft- und Kältetechnik GmbH and the Technischen Universität Dresden (Institut für Hydrobiologie und Institut für Siedlungs- und Industriewasserwirtschaft). Professor Dr Peter Krebs from the Institute for Urban and Industrial Water Management is the scientific director. The partners from TU Dresden also carried out the first preliminary investigations in a laboratory test facility for the degradation of DMAc with moving-bed biofilm reactors (MBBR). Based on these results, the Dresden environmental experts developed the implemented plant concept.

Multi-stage Plant for Wastewater-free Production

The pilot plant enables concept validation and definition of the essential process parameters under real conditions. In the plant, the wastewater first passes through an MBBR in which anoxic denitrification takes place. In the next process step, the solvent is degraded in a highly loaded, aerobically operated MBBR. Nitrification takes place in a downstream vertical filter system. “By coupling the two-stage MBBR with a near-natural process, a vertical filter, different process combinations and concentrations of the solvent for degradation can be tested,” explains Nadine Siebdrath, project manager at DAS Environmental Expert GmbH. “At the end of the project, we will know which of the processes is best suited for zero-liquid discharge, i.e. wastewater-free production.”

Resource-efficient and sustainable

“The Med-zeroSolvent project corresponds to what DAS EE has been advocating for over 15 years: consistent wastewater treatment at the point of origin and efficient processing for further use in production,” adds Nadine Siebdrath. “Thanks to intelligent processes, the process water remains in production, municipal wastewater treatment plants are not polluted with environmentally critical substances and the thermal disposal of partial wastewater quantities and the previously necessary truck transport are no longer necessary. This saves resources and is sustainable.

Team of Experts for scalable Treatment Modules

The research project combines proven technologies for industrial wastewater treatment with near-natural processes.

This is new, unique in this form and, thanks to its modular design, offers a wide range of applications for the energy-efficient treatment of organically polluted waste water.

Neben den biologischen Verfahren als einer Hauptkomponente der Prozesswasserbehandlung werden membrangestützte Verfahren für die Rückführung des aufbereiteten Wassers in den Prozess entwickelt. Als Resultat von Med-zeroSolvent sollen skalierbare Behandlungsmodule für Prozessabwässer entstehen, die auch anderweitig zur Behandlung von Abwässern mit ähnlicher Beschaffenheit eingesetzt werden können. Das Projekt läuft noch bis März 2024.