Clean Business – state-of-the-art wastewater technology for cosmetics manufacturers

Expand production and still reduce the pollutant load that enters the local wastewater system. This was the goal of an innovative manufacturer for cosmetics and care products from Germany. The company commissioned DAS Environmental Expert GmbH with the renewal and expansion of its wastewater treatment plant.

Wastewater Treatment 2.0 – modern and larger thanks to DAS

The internationally operating developer, manufacturer and packager of cosmetic and care products trusts DAS Environmental Expert GmbH for the renewal and capacity expansion of the existing wastewater treatment plant. Originally, the project only provided for modernization. But in dialogue with the Dresden-based environmental technology specialists, a combination of chemical-physical wastewater treatment was finally developed, which also takes into account the customer’s growth plans. This ensures that even with fluctuating wastewater volumes, reliable treatment takes place that reduces the load on the local wastewater treatment plant and always complies with all specifications.

With this plant, we have reached a new technical level in terms of plant design and degree of automation. In line with the state-of-the-art production lines at the cosmetics manufacturer’s plant, the latest environmental technologies have been installed. We are very proud of this.

Fluctuating Wastewater Volumes with varying Loads

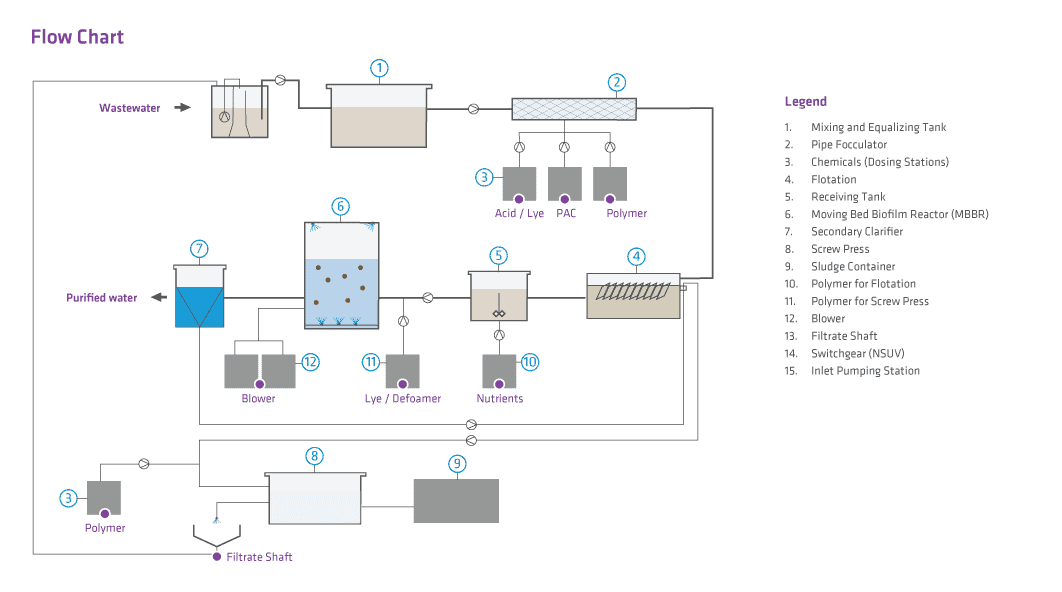

In production, the plants and the mobile transport units are cleaned after each batch. The wastewater treatment system therefore had to be designed for highly fluctuating wastewater volumes and a very complex, frequently changing load. Due to the manufacturer’s wide product range, the wastewater can contain a high proportion of emulsions and high COD loads. With a volume flow of 140 cubic meters per day, the goal was to reduce the COD from 10,000 to below 1,500 ppm. To reliably ensure this target, the DAS environmental technology experts installed a modern and highly automated wastewater treatment plant:

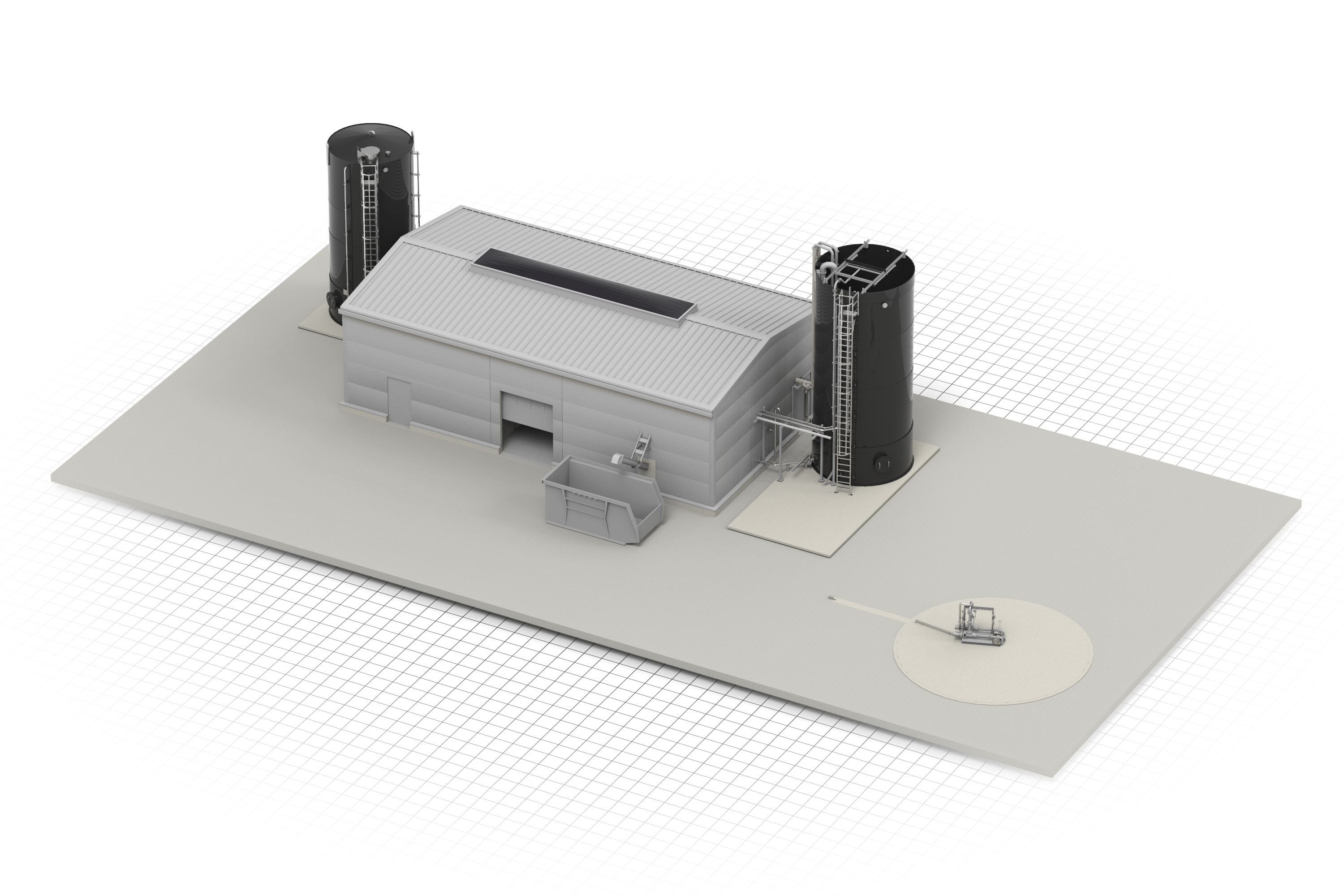

Relief of the communal Wastewater Treatment Plant by using a Moving Bed Biofilm Reactor

In order to relieve the local wastewater treatment plant, the pollutant separation of the plant is significantly improved by the innovations and supplemented by a biological pollutant degradation. The central element of the new plant is a Moving Bed Biofilm Reactor (MBBR) for COD degradation. It is located in the open air, as is a three-chamber system already in place at the client’s site, which was incorporated into the plant, and a large mixing and equalization tank. The other components were installed in a newly constructed hall.

Intelligent Process for reliable Wastewater Treatment

The production wastewater enters the existing three-chamber system via a collection line. There, sediment and fats are separated in chambers 1 and 2. From chamber 3 the wastewater is taken for further treatment. It is pumped into the mixing and equalization tank of the new wastewater treatment plant (WWTP).

In order to avoid overloading of the biological stage, the wastewater is pre-treated in a flotation unit with upstream pipe flocculator before entering the biological stage. The pH value is adjusted automatically with the aid of hydrochloric acid or caustic soda. Emulsions are broken down by the addition of polyaluminum chloride; the addition of a flocculant aids the separation of solids in the downstream dissolved air flotation. The flotation has its own control and switchgear, which interacts with the WWTP control system.

In the Fluidized Bed Reactor, Microorganisms break down organic Substances

Oxygen is supplied via a redundantly designed aeration unit. The air input also causes turbulence of the carrier material within the reactor. Freely suspended biomass is additionally present in the system in the form of activated sludge flocs.

Excess sludge is transported with the treated water to a secondary clarifier where it is separated by gravity before being conveyed by an eccentric screw pump to the flotate hopper. This is also where the separated solids (flotate) from flotation reach. A flotation sludge pump then conveys the sludge to the downstream sludge dewatering system. To guarantee functional reliability, there are two of these pumps. They are controlled in automatic mode depending on the filling level in the flotate hopper.

The clear water from the flotation, with an already reduced proportion of organic contents, then enters the biological stage via a receiving tank: In the fluidized bed reactor, the degradation of the organic contents takes place aerobically with the aid of microorganisms that grow in the form of a biofilm on a carrier material. To do this, the microorganisms require oxygen and nutrients such as ammonium nitrogen and orthophosphate . These substances are automatically added to the wastewater in the receiving tank via metering devices.

Wastewater Routing according to Demand

In order to better separate the free water, a flocculant is added to the sludge upstream of the sludge press with the aid of an inline polymer mixer. The sludge is then dewatered using a screw press; the remaining residue is removed from the building to a container using a screw conveyor. The outflowing water returns to the three-chamber system via a channel. In normal regular operation, intermediate pumps convey the wastewater from the receiving tank to the MBBR. Should it be necessary, however, the wastewater can also be fed back from there to the mixing and equalization tank; appropriate piping enables such recirculation if required.

Foaming as an additional Challenge

Since the cosmetics manufacturer’s wastewater often also contains a high level of detergents, foaming must be prevented in the plant. On the one hand, this is done by adding a biodegradable defoamer as required. In addition, a foam suppression system is installed at the head of the MBBR. By means of a pump, the wastewater is circulated and sprayed under pressure via a special nozzle system.

The new plant handles the increasing wastewater volumes constantly and efficiently. The required effluent value of COD <1,500 is reliably achieved; the hydraulic throughput was easily increased from the previous 80 to 120 to 140 cubic meters per day. At the same time, the setup offers room for further company growth: “If production is further expanded, the capacity of the wastewater treatment plant can also be increased without complications,” emphasizes Dr. Anita Haupt, Director Process Design at DAS Environmental Expert GmbH. “Overall, a plant has been created that is convincing all around in terms of layout and function.” The realization under corona conditions brought some challenges. Overall, however, the installation of the plant was uncomplicated.

The realization under corona conditions brought some challenges. Overall, however, the installation of the plant was without complications. “The winter of the century hit us right in the cold commissioning period. But with some quick frost protection measures, we also mastered this hurdle.

Your Contact for Wastewater Treatment in Cosmetics Manufacturing